Grade of carbide studs for HPGR :

| Grades | Density (g/cm³) |

Hardness (HRA) |

T.RS (N/mm²) |

Main Application |

| BTD15 | 14 | 86.5 | 2800 | High hardness,high toughness,mainly used for roller press rollers,suitable for cement crushing |

| BTD18 | 13.75 | 85 | 2800 | High hardness,high toughness,mainly used for roller press rollers,suitable for cement crushing |

| BTD20 | 13.5 | 84.5 | 3300 | high toughness,mainly used for roller press rollers,suitable for cement crushing |

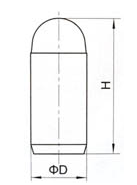

HPGR studs sizes:

| Type | Basic size(mm) | |

| Diameter(ΦD) | Height(H) | |

| BTSQ1640 | 16.2 | 40 |

| BTSQ1645 | 16.2 | 45 |

| BTSQ1040 | 10.2 | 40 |

Tungsten carbide studs for HPGR details:

Please send us inquiries for quotations and free samples for testing: