Tungsten carbide sandblasting nozzle grade:

| Grade | Composition (%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm²) |

| YG6 | 6%co 94%wc | 14.85 | ≥92.5 | ≥2000 |

| YG8 | 8%co 92%wc | 14.7 | ≥89.8 | ≥2800 |

| YG10X | 10%co 90%wc | 14.35 | ≥91.5 | ≥3600 |

| YG11 | 11%co 89%wc | 14.4 | ≥88.5 | ≥2900 |

| YG6 | Fine grain alloy, good wear resistance. It is suitable for making carbide nozzles, wear-resistant parts, etc. |

| YG8 | High bending strength, wear resistance lower than YG6. It is suitable for making carbide nozzles, wear-resistant parts, etc. |

| YG11 |

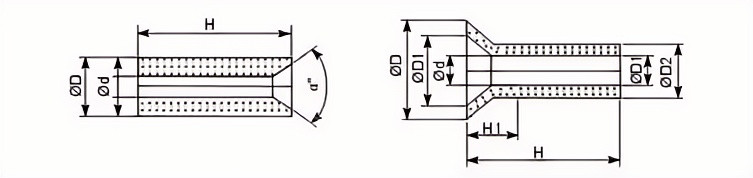

Tungsten carbide sandblasting nozzle sizes:

| D | D1 | D2 | d | d1 | H | HI | a° |

| 15 | 4 | 20-60 | 50 | ||||

| 15 | 5 | 20-60 | 50° | ||||

| 15 | 6 | 20-60 | 50° | ||||

| 16 | 5 | 20-60 | 50 | ||||

| 16 | 6 | 20-60 | 50° | ||||

| 16 | 8 | 20-60 | 50° | ||||

| 20 | 6 | 20-80 | 55° | ||||

| 20 | 8 | 20-80 | 55° | ||||

| 20 | 10 | 20-80 | 55° | ||||

| 21 | 10 | 20-80 | 55° | ||||

| 32.5 | 26 | 19.5 | 8 | 14 | 80-170 | 50 | |

| 32.5 | 26 | 19.5 | 10 | 14 | 80-170 | 50 | |

| 32 | 25 | 12.5 | 4 | 50-080 | |||

| 32 | 25 | 12.5 | 6 | 50-80 |

Custom sizing is also available. Please provide us with your specifications.

Tungsten carbide sandblasting nozzle details:

Carbide Sandblasting Nozzles – Product Features:

1. Superior Hardness, Ultimate Wear Resistance

Hardness reaches HRA 89-93: The material’s hardness is second only to diamond, giving the nozzle extremely high resistance to erosion.

Extra-Long Service Life: Compared to ordinary ceramic nozzles, lifespan is increased by 5-10 times; compared to steel nozzles, lifespan is increased by more than 20 times. Significantly reduces replacement frequency and downtime.

2. Unique Venturi Design, Doubled Efficiency

Acceleration Principle: Utilizes a precisely calculated Venturi flow channel design (inlet contraction – straight throat – outlet expansion). When compressed air carrying abrasive particles passes through, the airflow velocity can increase to above the speed of sound.

2.1 Significant Results:

Abrasive exit velocity increased by 30%-50%;

Stronger impact force, cleaning efficiency increased by more than 40%;

Concentrated jet beam, larger coverage area, ensuring uniform surface treatment.

3. Excellent Impact Resistance and Toughness

Scientific Formula: Utilizing a “hard phase (WC) + binder phase (Co)” structure, by adjusting the cobalt content (e.g., YG6, YG8 grades), it maintains high hardness while imparting sufficient toughness to the matrix.

Durable and Reliable: Capable of withstanding continuous high-speed impacts from large, high-hardness abrasive particles (such as steel shot and copper ore sand) without easily cracking, chipping, or breaking.

4. Precision Machining and Dimensional Accuracy

High-Precision Forming: Employing isostatic pressing or molding, combined with subsequent precision grinding of the inner and outer diameters.

Small Internal Hole Tolerance: The inner diameter tolerance is controlled within ±0.05mm, with a mirror-like smooth inner wall. This ensures smooth airflow channels, reduces eddy current losses, thereby maintaining a stable injection angle and pressure, and reducing energy consumption.

5. Good High-Temperature Resistance and Chemical Stability

High-Temperature Resistance: Can operate for extended periods in high-temperature environments (withstanding temperatures up to 400°C-600°C) without performance degradation.

Corrosion resistant: It has good resistance to chemical media such as acids and alkalis, and is suitable for working environments in sandblasting rooms that are humid or contain corrosion inhibitors. It is not easy to rust or corrode.

6. Wide range of applications: covering various industrial sandblasting operations such as shipbuilding and repair, auto parts, steel structure corrosion protection, mold cleaning, and surface strengthening/descaling of aerospace components.

Please send us inquiries for quotations and free samples for testing: