Grades of tungsten carbide rolls:

|

Grade |

Wc (%) |

Co (%) |

TRS |

Density (g/cm³) |

Hardness (HRA ) |

| YG15 | 85 | 15 | ≥2500 | 13.9-14.1 | ≥87 |

| YGH30 | 85 | 15 | ≥2700 | 14.02 | ≥84.9 |

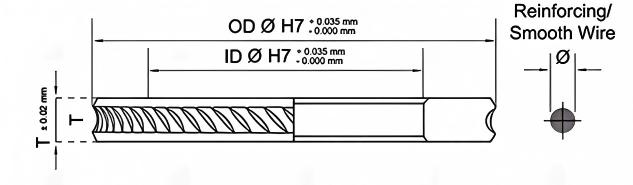

Sizes of tungsten carbide rolls:

| Wire Range | Outside φ (mm) | Inside φ (mm) | Thickness (mm) |

| 4-8.5 | 123 | 82 | 15 |

| 9-12 | 123 | 82 | 20 |

| 4-8.5 | 125 | 82 | 15 |

| 9-12 | 125 | 82 | 20 |

| 4-8.5 | 140 | 90 | 15 |

| 9-12 | 140 | 90 | 20 |

| 4-8.5 | 150 | 90 | 15 |

| 9-12 | 150 | 90 | 20 |

Details of tungsten carbide rolls:

Please send us inquiries for quotations and free samples for testing: