Grades of tungsten carbide anvils:

|

Grade |

Co% |

Density(g/cm³) |

Hardness (HRA) |

TRS |

| BTN8 | 8 | 14.7 | 91.5 | 3500 |

| BTN10 | 10 | 14.5 | 92 | 3800 |

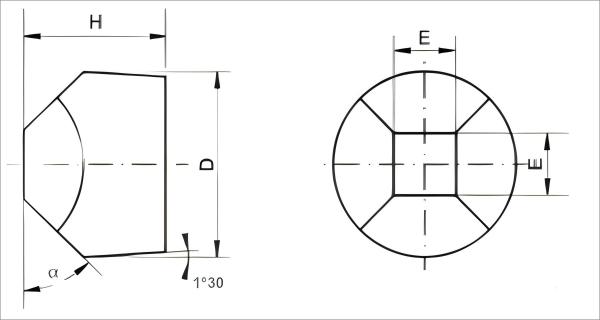

Sizes of tungsten carbide anvils (MM):

| Type | D | E | H | a | |||

| Metric size | Allowable deviation | Metric size | Allowable deviation | Metric size | Allowable deviation |

46° |

|

| TCA636 | 105.5 | +1.5 -0.5 |

35.6 | ±0.5 | 76 | +2.0 -0.5 |

46° |

| TCA646 | 116 | +1.7 -0.5 |

43 | ±0.6 | 82.5 | +2.0 +0.5 |

46° |

| TCA645-2 | 129 | 2 | 44.5 | ±0.5 | 96 | +2.5 +0.5 |

46° |

| TCA647-2 | 122 | +2.0 +0.7 |

47 | ±0.5 | 90 | +2.0 +0.7 |

46° |

| TCA648 | 129 | +3.6 +1.6 |

48 | ±0.5 | 101 | 1 | 46° |

| TCA648-6 | 129 | 2 | 47.5 | ±0.5 | 96.4 | 1 | 46° |

| TCA652 | 129 | +1.5 -0.5 |

52 | ±0.5 | 93 | +2.0 +1.0 |

46° |

| TCA661 | 160 | +2.5 +1.5 |

61 | ±0.5 | 115 | +2.5 +1.5 |

46° |

| TCA665-6 | 175 | +4.0 +2.0 |

65.5 | ±0.5 | 129 | +3.0 +1.0 |

46° |

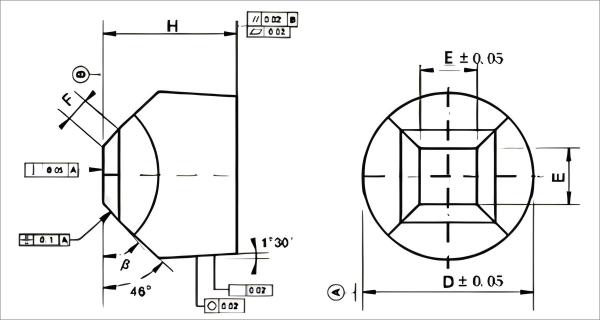

| Series | Type | Dimensions | ||||

| D | E | H | F | β | ||

|

φ103 |

GDCΦ103/32.5×12.5×41×76 | 103 | 32.5 | 76 | 12.5 | 41° |

| GDCφ103/32.5×11.5×41×75.5 | 103 | 32.5 | 75.5 | 11.5 | 41° | |

|

φ105 |

GDCφ105/32.5×12.5×41.5×75.5 | 105 | 32.5 | 75.5 | 12.5 | 41.5° |

| GDCφ105/33×12.5×41×76 | 105 | 33 | 76 | 12.5 | 41° | |

|

φ110 |

GDCφ110.2/38×13×41.5×80 | 110.2 | 38 | 80 | 13 | 41.5° |

| GDCφ110.3/39×13×41.5×80 | 110.3 | 39 | 80 | 13 | 41.5° | |

| φ114 | GDCφ114.6/39.5×13×41.5×82.5 | 114.6 | 39.5 | 82.5 | 13 | 41.5° |

|

Φ115 |

GDCφ115/38×13×41×82.5 | 115 | 38 | 82.5 | 13 | 41° |

| GDCφ115.1/38.5×14×41.5×82.5 | 115.1 | 38.5 | 82.5 | 14 | 41.5° | |

| GDCΦ115.6/39.5×13×41.5×82.5 | 115.6 | 39.5 | 82.5 | 13 | 41.5° | |

| GDCΦ115.3/39×13×41.5×82.5 | 115.3 | 39 | 82.5 | 13 | 41.5° | |

| GDCΦ115.9/40×13×42×82.5 | 115.9 | 40 | 82.5 | 13 | 42° | |

| GDCφ115.2/41×13×42×82.5 | 115.2 | 41 | 82.5 | 13 | 42° | |

| GDCΦ115/41×13×41.5×82.5 | 115 | 41 | 82.5 | 13 | 41.5° | |

|

φ122 |

GDCφ112/43×12×41×91 | 112 | 43 | 91 | 12 | 41° |

| GDCφ112.3/43×13×41×91 | 112.3 | 43 | 91 | 13 | 41° | |

| GDCΦ112.4/43×13×41.5×91 | 112.4 | 43 | 91 | 13 | 41.5° | |

| GDCΦ112.8/43.5×13×41.5×90 | 112.8 | 43.5 | 90 | 13 | 41.5° | |

|

φ127 |

GDCΦ127/43.5×13×41.5×95 | 127 | 43.5 | 95 | 13 | 41.5° |

| GDCΦ127.8/43.5×13×41×95 | 127.8 | 43.5 | 95 | 13 | 41° | |

| GDCΦ127.3/44×13×41.5×95 | 127.3 | 44 | 95 | 13 | 41.5° | |

| GDCΦ127.4/46×13.5×41.5×95 | 127.4 | 46 | 95 | 13.5 | 41.5° | |

| GDCΦ127.8/46×12×41.5×95 | 127.8 | 46 | 95 | 12 | 41.5° | |

| φ128 | GDCφ128/46×13×41.5×95 | 128 | 46 | 95 | 13 | 41.5° |

| φ142 | GDCφ142/49×15×41.5×102 | 142 | 49 | 102 | 15 | 41.5° |

| Φ148 | GDCφ148.5/54×15×41.5×100 | 148 | 54 | 100 | 15 | 41.5° |

| Φ160 | GDCΦ160/55.5×15×41.5×115 | 160 | 55.5 | 115 | 15 | 41.5° |

| Φ175 | GDCΦ175/63×15×41.5×128 | 175.32 | 63 | 128 | 15 | 41.5° |

| Φ160 | GDCΦ160/57×15×41.5×115 | 160 | 57 | 115 | 15 | 41.5° |

| φ199 | GDCφ199/76×22×41.5×142 | 199 | 76 | 142 | 22 | 41.5° |

Custom sizing is also available. Please provide us with your specifications.

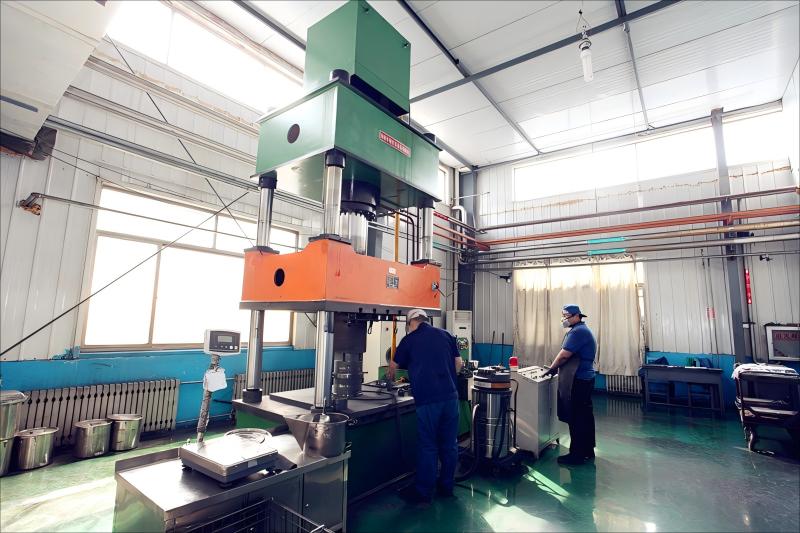

Tungsten carbide anvils pressing 1200T, which can make OD 240MM anvils:

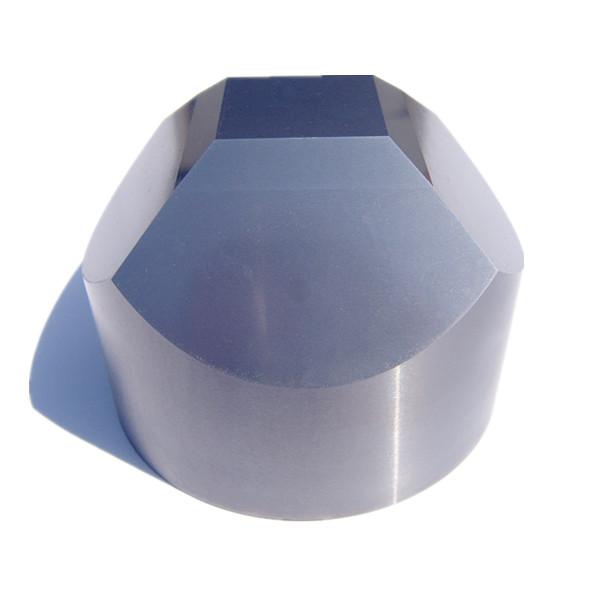

Details of carbide anvils:

Three-coordinate dimensional inspection of precision-ground tungsten carbide anvil:

Precautions for using of carbide anvils:

1.Residual Stress Relief

Anvils retain residual stress after finish machining. Prior to use, aging treatments such as natural aging, oven aging, oil boiling, vacuum aging, or ultrasonic aging must be performed. Natural aging requires ≥1 month; oven aging must be conducted at ≤250°C for ≥72 hours.

2.Anvil Assembly Specifications

The tapers of the anvils and steel rings must match, with a contact area ≥90%. Press-fit height should be 8–10 mm for diameters <127 mm and 10–12 mm for diameters ≥127 mm. Avoid point contact between anvils and size spacers to prevent stress concentration.

3.Raw/Auxiliary Material Requirements

Steel rings and size spacers must meet machining accuracy standards. Inner wall surface finish of steel rings: Ra 1.6. Ovality and taper must match anvil geometric tolerances. Size spacer parallelism ≤0.02 mm; hardness must be appropriate.

Pyrophyllite roasting temperature and duration must be controlled to ensure proper pressure transmission and prevent moisture-related explosions.

Conductive steel rings must be rust-free, crack-free, stored dry, and show no blueing (oxidation) after baking.

4.Equipment Requirements

The press must have precise adjustment capability, no leaks, and synchronism/neutrality deviation ≤0.2 mm.

5.Operational Requirements

During assembly:

Inspect pyrophyllite for cracks/impurities and verify correct orientation of thin/thick steel discs.

Clean all six anvil surfaces before installation to avoid crushing or electrical discharge.

Ensure all four sides of each anvil are properly aligned to prevent failure/explosion.

Check cylinder movement: fixed cylinders must not misoperate; moving cylinders must pause at position.

Maintain pressure for ≥1 minute after heating stops to prevent rupture during pressure release.

Please send us inquiries for quotations and free samples for testing: