Tungsten carbide tubes grades:

| Grade | Composition (%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm²) |

| YG6 | 6%co 94%wc | 14.85 | ≥92.5 | ≥2000 |

| YG8 | 8%co 92%wc | 14.7 | ≥89.8 | ≥2800 |

| YG10X | 10%co 90%wc | 14.35 | ≥91.5 | ≥3600 |

| YG11 | 11%co 89%wc | 14.4 | ≥88.5 | ≥2900 |

| YG6 | Fine grain alloy, good wear resistance. It is suitable for making carbide tubes, carbide sleeves, tungsten carbide bushings, wear-resistant parts, etc. |

| YG8 | High bending strength, wear resistance lower than YG6. It is suitable for making carbide tubes, tungsten carbide sleeves, carbide bushings, wear-resistant parts, etc. |

| YG11 |

Tungsten carbide tubes uses:

Carbide tubes are widely used in many fields, mainly including petrochemical, mould industry, submersible oil pumps, slurry pumps, water pumps, centrifugal pumps and other industrial equipment. In these applications, carbide tubes are mainly used to reduce wear, seal and protect components, and have the characteristics of high hardness resistance, high corrosion resistance, pressure resistance, wear resistance and high bending strength.

In addition, carbide sleeves also play an important role in the following specific application fields:

Valve application: In valves, carbide tubes are installed in the stem cover steam trap to reduce valve leakage and seal.

Mould: used to manufacture wear-resistant and corrosion-resistant moulds, such as wire drawing moulds, stamping moulds, etc.

Petroleum industry: In the process of oil exploration, carbide wear-resistant tubes are widely used in various mechanical equipment, carbide wear-resistant sleeves are used to oil extraction pump components to ensure stable operation of equipment in rugged drilling environments, greatly improving drilling efficiency.

Other types of carbide tubes:

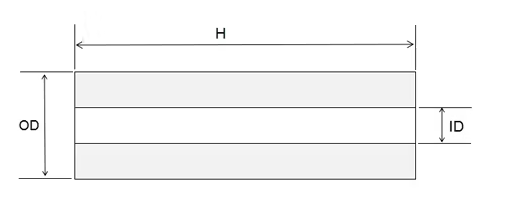

Carbide tubes sizes:

| Dimensions | Remark | ||

| OD | ID | H | |

| 5-800 mm | 4-790 mm | 10-600 mm | Customized sizes are also available |

We can make the carbide tubes as per your drawings.

Please send us inquiries for quotations and free samples for testing: