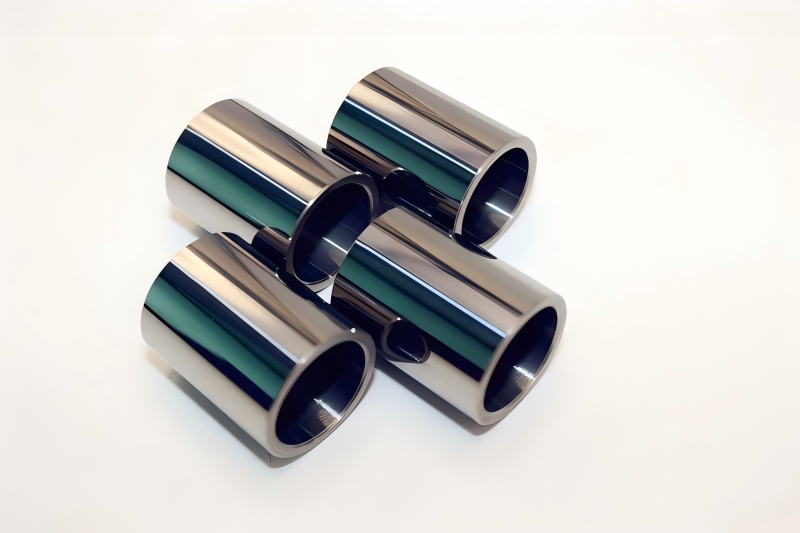

Tungsten carbide shaft sleeve grades:

| Grade | Composition (%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm²) |

| YG6 | 6%co 94%wc | 14.85 | ≥92.5 | ≥2000 |

| YG8 | 8%co 92%wc | 14.7 | ≥89.8 | ≥2800 |

| YG10X | 10%co 90%wc | 14.35 | ≥91.5 | ≥3600 |

| YG11 | 11%co 89%wc | 14.4 | ≥88.5 | ≥2900 |

| YG6 | Fine grain alloy, good wear resistance. It is suitable for making carbide sleeves and tungsten carbide bushings, wear-resistant parts, etc. |

| YG8 | High bending strength, wear resistance lower than YG6. It is suitable for making carbide sleeves and carbide bushings, wear-resistant parts, etc. |

| YG11 |

Tungsten carbide shaft sleeve uses:

1.Petroleum and Natural Gas Industry

Used in mud motor bearings for drilling equipment to resist sand erosion and extend service life by 3-5 times.

Shaft support for submersible oil pumps and slurry pumps, capable of withstanding high pressure (up to 25MPa) and preventing medium leakage.

2.Chemical and Corrosion-Resistant Environments

In refinery FCC units, resistant to high temperatures of 400°C and sulfur-containing media erosion, significantly outperforming stainless steel sleeves in service life.

Low surface roughness (below Ra 0.2μm) reduces fluid resistance and improves pump efficiency by 5%-8%.

3.High-Load Mechanical Transmission

In equipment such as mining crushers and steel rolling mills, capable of withstanding cyclic loads with compressive strength up to 6800MPa.

After application in steel rolling mills, bearing service life increased from 800 hours to 5000 hours.

4.Precision Equipment and Specialized Industries

Sealing components for aerospace turbine engines, maintaining dimensional stability at 1000°C high temperatures.

Wafer dicing spindle positioning accuracy reaches ±2μm, reducing defect rates.

Details of tungsten carbide shaft sleeve:

We can make the carbide shaft sleeves as per your drawings.

Please send us inquiries for quotations and free samples for testing: