Does tungsten carbide rust?

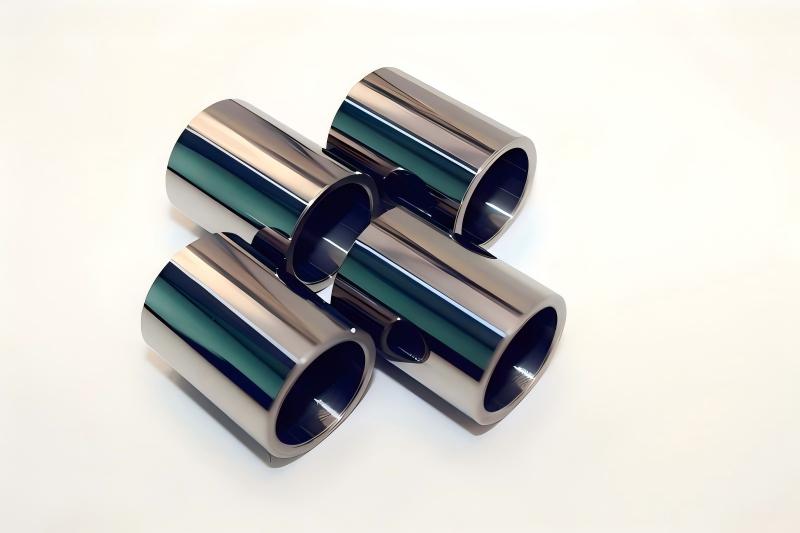

Does tungsten carbide rust? Pure tungsten carbide itself does not rust, as it is chemically stable, resistant to oxidation or corrosion. Composed of tungsten and carbon, tungsten carbide is insoluble in water, hydrochloric acid, and sulfuric acid. In daily use, it maintains its metallic luster and does not easily discolor. In industrial applications, pure-phase tungsten carbide is difficult to use directly. It is typically combined with cobalt, nickel, iron, or other materials as a binder phase to form a composite material for practical use.

In the industrial field, tungsten carbide is renowned for its high hardness and wear resistance, earning it the title “industrial teeth” and is often considered a “rust-proof” material. However, in practice, some tungsten carbide products may develop rust stains, spots, or even experience performance degradation, which puzzles many users. Does tungsten carbide actually rust? In fact, the rusting of tungsten carbide is not an issue with the material itself. The core reasons lie in the binder phase composition within the material and the service environment. What actually undergoes oxidative corrosion is the binder metal, not the tungsten carbide hard phase itself.

I. Why Does Pure Tungsten Carbide Not Rust?

To understand the corrosion resistance of tungsten carbide, it is essential to first clarify the nature of rusting. Rusting typically refers to the oxidation reaction of metals in the presence of oxygen, water, etc., forming loose oxides (e.g., iron rust forms Fe₂O₃・nH₂O). The corrosion resistance of tungsten carbide stems from its unique composition and structure:

From a compositional perspective, tungsten carbide is an interstitial compound formed from tungsten (W) and carbon (C) through high-temperature sintering, exhibiting extremely strong chemical stability. Tungsten itself is a high-melting-point, highly inert metal that hardly reacts with oxygen or water at room temperature. When combined with carbon to form WC crystals, the atoms are tightly bound by covalent and metallic bonds, resulting in a dense crystal structure with no free metal atoms available for oxidation.

From a structural perspective, the microstructure of tungsten carbide is a composite system of “hard phase + binder phase”: WC particles serve as the hard phase, typically accounting for 80%-97%, forming a continuous, dense skeleton that acts like “armor” to isolate external corrosive media. The binder phase constitutes only 2%-20%, connecting the WC particles to form an integrated material. Therefore, the pure WC hard phase itself does not undergo oxidative reactions with the environment and naturally does not exhibit rusting.

II. Which Types of Tungsten Carbide Rust? The Core Lies in the Binder Phase.

The rusting of tungsten carbide products is essentially the oxidative corrosion of the binder phase metal. The chemical activity of different binder phases directly determines the product’s corrosion resistance and risk of rusting.

1.Iron-Based Binder Phase Tungsten Carbide: Prone to Rusting.

Some low-cost tungsten carbide products use iron (Fe) or nickel-iron (Ni-Fe) alloys as the binder phase. Iron is a chemically active metal. Once exposed to humid air, rainwater, or acidic/alkaline environments, it rapidly undergoes oxidation: Fe + O₂ + H₂O → Fe₂O₃・nH₂O (iron rust).

The rusting characteristics of such tungsten carbide are very apparent: reddish-brown spots or continuous rust layers appear on the surface, affecting not only appearance but also causing structural damage. The rust, being loose in texture, gradually flakes off, exposing more iron-based binder phase inside and creating a vicious cycle of corrosion. This eventually leads to decreased hardness, loss of wear resistance, and even fracture.

Iron-based binder phase tungsten carbide is typically used in scenarios with extremely low corrosion resistance requirements (e.g., rough cutting tools in general machining, low-load wear-resistant parts). It is low-cost but must never be used in humid, outdoor, or corrosive environments.

2.Cobalt-Based Binder Phase Tungsten Carbide: Rusts Only Under Specific Conditions.

Mainstream high-performance tungsten carbide products mostly use cobalt (Co) as the binder phase. Cobalt is chemically much more inert than iron and exhibits strong stability in dry air and neutral environments at room temperature, so such products are generally considered rust-resistant. However, cobalt is not absolutely corrosion-resistant. Under the following special conditions, oxidative corrosion can still occur (though not traditional red rust, it is considered rusting in a broader sense):

Prolonged immersion in saltwater or chlorine-containing media: e.g., marine environments, chlorine-containing solutions in the chemical industry. Chloride ions can destroy the passive film on the cobalt surface, causing pitting corrosion and forming black CoO or brown-black Co₃O₄ oxide layers.

Strong acid and strong alkali environments: In strong acids like hydrochloric or sulfuric acid, or strong alkalis like sodium hydroxide, cobalt’s passive film can dissolve, leading to chemical corrosion, surface pitting, and even weight loss.

High temperature, high humidity, and abundant oxygen: e.g., high-temperature steam environments, long-term outdoor exposure to sun and rain can accelerate cobalt oxidation. Although the oxide layer is relatively dense, long-term accumulation can affect surface finish and performance.

Damaged surface coatings: If tungsten carbide products have anti-corrosion coatings like chrome plating or nitriding, damage to the coating exposes the internal cobalt-based binder phase, allowing corrosive media direct contact and causing localized rusting.

Rusting in cobalt-based binder phase tungsten carbide is mostly localized oxidation, not widespread loose rust like with iron-based products. However, it can still affect product lifespan and precision, especially in high-precision, high-reliability applications.

3.Nickel-Based Binder Phase Tungsten Carbide: Highly Corrosion-Resistant, the Preferred Choice for Rust Prevention.

Tungsten carbide using nickel (Ni) or nickel-chromium alloys as the binder phase offers the best corrosion resistance currently available and is almost rust-free in conventional environments. Nickel is chemically much more inert than cobalt and iron. At room temperature, it forms a dense, passive oxide film on its surface that effectively blocks oxygen, water, and most corrosive media, maintaining stability even in humid or mildly acidic/alkaline environments.

Even in some complex environments, nickel-based binder phases demonstrate outstanding corrosion resistance. They exhibit strong tolerance to neutral salt spray and weakly acidic solutions. In salt spray tests, their corrosion resistance time can be 3-5 times that of cobalt-based products. Corrosion may only occur under extreme conditions such as exposure to strong oxidizing acids (e.g., concentrated nitric acid, chromic acid solutions) or high-temperature molten salts. Additionally, nickel-based binder phases offer good resistance to stress corrosion cracking, meaning they are less prone to cracking under load while exposed to corrosive media. Therefore, nickel-based tungsten carbide is often used in applications with extremely high corrosion resistance requirements. Its only drawback is higher cost, priced about 1.5-2 times that of standard cobalt-based tungsten carbide. Furthermore, its wear resistance at room temperature is slightly lower than that of cobalt-based products, requiring a balance between corrosion resistance and wear resistance.

III. Which Industries and Products Need to Pay Special Attention to Tungsten Carbide Rusting?

Since the rusting of tungsten carbide is essentially the corrosion failure of the binder phase, industries where the operating environment involves humidity, corrosive media, or high precision must prioritize corrosion resistance (i.e., rust prevention) as a key selection criterion:

1.Marine Engineering Industry

The marine environment is a high-risk area for tungsten carbide rusting. Seawater contains high concentrations of chloride ions and is perpetually humid with salt spray. Tungsten carbide products used in this industry, such as underwater cutting tools, valve cores, and wear-resistant components on drilling platforms, will rust severely in a short time if made with iron-based binder phases. Even cobalt-based products require special anti-corrosion treatments (e.g., ceramic coatings, passivation) to prevent pitting corrosion.

2.Chemical Industry

Chemical production often involves strong corrosive media like acid/alkali solutions and organic solvents. Tungsten carbide components such as reactor linings, pipeline wear-resistant parts, and impeller blades can be corroded if the binder phase lacks sufficient corrosion resistance, leading to rusting, failure, and even contamination of materials. Therefore, this industry typically selects tungsten carbide with high cobalt content (e.g., above 12% Co) or corrosion-resistant types with alloying elements like chromium or molybdenum.

3.Food Processing Industry

Food processing equipment (e.g., meat cutting blades, biscuit molds, beverage filling valves) frequently contacts water, steam, and acidic/alkaline cleaning agents, requiring rust-free products to avoid contaminating food. Such products must use cobalt-based tungsten carbide, with surfaces polished and passivated to prevent binder phase oxidation and rust spot formation that could contaminate food.

4.Medical Industry

Tungsten carbide products in the medical field (e.g., surgical instrument edges, wear-resistant coatings on artificial joints) are in long-term contact with bodily fluids (containing salts, proteins, etc.). While bodily fluids are not highly corrosive, they demand extremely high biocompatibility and corrosion resistance. If cobalt-based binder phases oxidize, not only can product performance be affected, but cobalt ion leaching may also pose health risks. Therefore, medical-grade corrosion-resistant tungsten carbide must be used.

5.Automotive Manufacturing and New Energy Industries

Components like valve seat rings and fuel injector wear parts in automotive engines, as well as electrode sheet cutting tools in new energy battery production, operate in environments with high temperatures, humidity, or electrolytes. Rusting of tungsten carbide can lead to decreased component precision, accelerated wear, and affect engine efficiency or battery product quality. Therefore, cobalt-based tungsten carbide resistant to high/low temperatures and electrolyte corrosion is required.

6.Mold and Precision Machinery Industry

Components in cooling channels of injection or stamping molds, and wear-resistant parts like tools and guideways in precision machine tools, are in long-term contact with cooling water or cutting fluids (containing additives with some corrosiveness). These products demand extremely high precision; even slight rusting can affect machining accuracy. Therefore, tungsten carbide resistant to cutting fluid corrosion should be selected, with regular surface maintenance.

Conclusion:

The rusting of tungsten carbide is not an inherent property of the material itself but rather the oxidative corrosion of the binder phase metal under specific environmental conditions. Iron-based binder phases are prone to rusting, while cobalt-based phases only oxidize under special conditions like strong corrosion or prolonged humidity. For trade product selection, product specification, or brand building, it is crucial to precisely match the binder phase type based on the target industry’s operating environment. Iron-based is suitable only for dry, non-corrosive scenarios; cobalt-based suits most scenarios; and strong corrosive environments require additional anti-corrosion coatings. This approach prevents product complaints or performance failures due to rusting issues. Understanding the logic behind tungsten carbide’s corrosion resistance reflects professional expertise and is key to ensuring product competitiveness.

Our company is among China’s top ten tungsten carbide products manufacturers. Should you require cemented carbide products, please contact us.