Brazed carbide tips grades:

| Carbide Grade |

ISO Grade |

ANSI Grade |

Physical and Chemical Property | Performance & Applications | ||

| Density (G/CM3) | TRS (N/MM2) | Hardness(HRA) | ||||

|

YT15 |

P10 |

C7 |

11.3 |

1650 |

92 |

High wear resistance with good impact toughness. Suitable for semi-finishing of medium chip loads, or finishing of light chip loads on steel, cast steel, and alloy steel. |

|

YT14 |

P20 |

C6 |

11.4 |

1750 |

91.5 |

High strength, good impact and shock resistance. Suitable for rough turning and finish milling of carbon steel and alloy steel in continuous cutting, as well as semi-finishing and finishing in interrupted cutting. |

|

YT5 |

P30 |

C5 |

12.9 |

2200 |

90.5 |

Best strength and high impact and shock resistance among WC-Co-Ti alloys, but comparatively lower wear resistance. Suitable for rough turning, rough planing, and semi-finish planing of carbon steel and alloy steel. |

|

YW1 |

M10 |

—— |

13 |

1710 |

92.5 |

Good red hardness and resistance to impact loads. A good general-purpose grade. Suitable for machining ordinary steel, cast iron, as well as hard-to-machine steels such as refractory steel, high manganese steel, and stainless steel. |

|

YW2 |

M20 |

—— |

12.9 |

1880 |

91 |

High wear resistance and strength, resistant to high-impact loads. Suitable for roughing and semi-finishing of ordinary steel, cast iron, as well as refractory steel, high manganese steel, and high-grade alloy steel. |

|

YG6X |

K15 |

C3 |

14.9 |

1890 |

91.5 |

A fine-grained WC alloy with wear resistance higher than YG6 and strength close to YG6. Suitable for machining chilled alloy cast iron and refractory alloy steel, as well as for finishing ordinary cast iron. |

|

YG6 |

K20 |

C2 |

14.9 |

2050 |

90.5 |

High wear resistance and good impact and shock resistance. Suitable for semi-finishing and finishing of cast iron, non-ferrous metals, alloys, and non-metallic materials at moderate cutting speeds. |

|

K30 |

C1 |

14.7 |

2520 |

90 |

High strength and good impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast iron, non-ferrous metals, alloys, and non-metallic materials at low speeds. | |

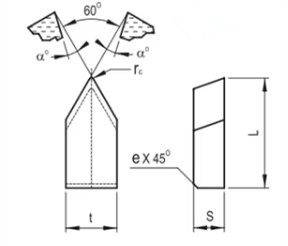

Tungsten carbide brazed tips sizes:

| TYpe | Dimension(MM) | |||||

| L | t | S | re | e | α° | |

| C110 | 10 | 4 | 3 | 0.5 | 一 | 一 |

| C116 | 16 | 6 | 4 | 0.5 | 0.8 | 10 |

| C120 | 20 | 8 | 5 | 0.5 | 0.8 | 10 |

| C122 | 22 | 10 | 6 | 0.5 | 0.8 | 10 |

| C125 | 25 | 12 | 7 | 0.8 | 0.8 | 10 |

Brazed carbide tips details:

Please send us inquiries for quotations and free samples for testing: