Tungsten steel plate, block & sheet grades:

| Grade | Composition (%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm²) |

| YG6A | 6%co 94%wc | 14.85 | ≥92.5 | ≥2000 |

| YG8 | 8%co 92%wc | 14.7 | ≥89.8 | ≥2800 |

| YG10X | 10%co 90%wc | 14.35 | ≥91.5 | ≥3600 |

| YG11 | 11%co 89%wc | 14.4 | ≥88.5 | ≥2900 |

| YG15 | 15%co 85%wc | 14 | ≥87.0 | ≥3000 |

| YG20 | 20%co 80%wc | 13.5 | ≥85.5 | ≥2800 |

| YG13X | 13%co 87%wc | 14.2 | ≥90.0 | ≥3200 |

| BT15 | 10%co 90%wc | 14.35 | ≥92.2 | ≥3900 |

| YG6A | Fine grain alloy, good wear resistance. It is suitable for manufacturing forming cutter, wear-resistant parts etc. For forming cutter, it is suitable for machining aluminium magnesium alloy, graphite, plastic and composite material, etc. |

| YG8 | High bending strength, wear resistance lower than YG6A, suitable for manufacturing forming cutter, wear-resistant parts etc. |

| YG11 | |

| YG15 | Suitable for manufacturing punching dies, wear-resistant parts etc. |

| YG20 | High bending strength, suitable for manufacturing progressive dies and other punching dies. |

| YG13X | |

| BT15 | Ultra-fine grain size, High performance, making cutting tools, suitable for cutting ordinary alloy steel, aluminum alloy, heat resistant alloy, cast iron, etc. |

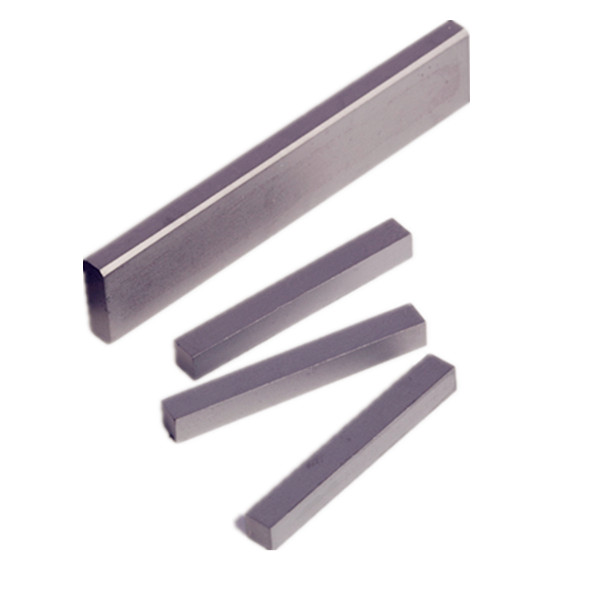

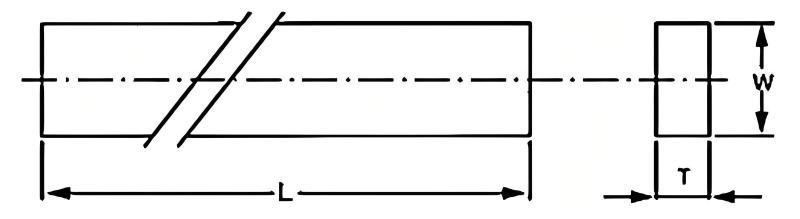

Tungsten steel plate, block & sheet sizes:

| Length L(mm) |

Width W(mm) |

Thicknes T(mm) |

Length Tolerance(mm) |

Width Toleranee(mm) |

Thickness Tolerance(mm) |

| 330 | 2~3 | 1~3 | +7.0 +3.0 |

+0.4 +0.2 |

+0.35 +0.15 |

| 330 | 3~8 | 1~3 | +7.0 +3.0 |

+0.5 +0.3 |

+0.35 +0.15 |

| 330 | 8~14 | 2~5 | +7.0 +3.0 |

+0.5 +0.3 |

+0.35 +0.15 |

| 330 | 14~34 | 2~11 | +7.0 +3.0 |

+0.6 +0.4 |

+0.5 +0.2 |

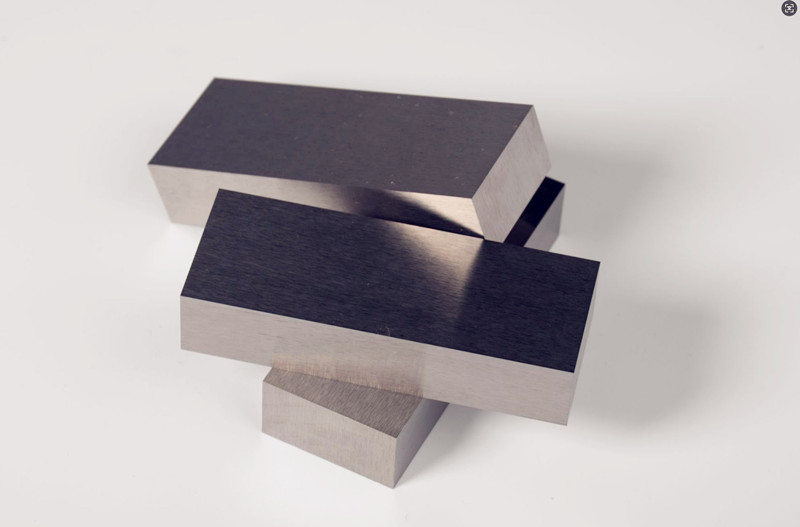

Tungsten steel plate, block & sheet details:

Primary Applications of tungsten steel plate, block & sheet:

With high wear resistance, impact resistance and dimensional stability, tungsten steel plate, block & sheet offer key solutions for harsh industrial conditions. Main applications:

1.Wear-Resistant Components & Liners

Processed into mining equipment liners, pump flow-through parts (for abrasive slurries), cement chute liners and conveyor scraper blades. Core function: Prevent wear from high-velocity granular materials (ores, sand, coal powder), greatly extending equipment life and reducing downtime.

2.Precision Stamping & Forming Dies

Blanking Dies: For silicon steel sheet blanking, electronic lead frame stamping, ceramic tile extrusion. Service life tens to hundreds of times longer than steel dies, ensuring mass production dimensional consistency.

Drawing Dies: For metal wire/rod drawing and cup deep drawing. Low friction and high surface finish reduce workpiece scratches.

Cold Heading/Extrusion Dies: Adapt to room-temperature metal forming, withstanding high pressure and wear.

3.Precision Measurement & Positioning Parts

Used to make gauge blocks, precision caliper heads, V-shaped positioning seats and machine tool guide sliders. Extremely low thermal expansion and corrosion resistance ensure long-term measuring accuracy and prevent wear-induced gaps in positioning parts.

4.Custom Tool Substrates

Processed via wire cutting or precision grinding into lead cutters, PCB V-groove knives and special-shaped shears. Suitable for cutting solid wood, particleboard, engineering plastics, cast steel, cast iron and stainless steel.

Please send us inquiries for quotations and free samples for testing: