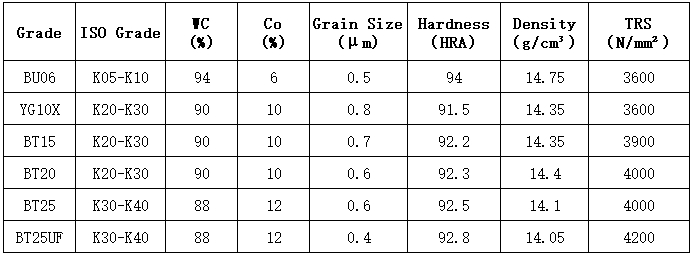

Tungsten carbide drill bit blanks grades:

Grade BU06: This grade is suitable for machining aluminum magnesium alloy, graphite, plastic, wood and composite material, etc.

Grade YG10X: This grade is suitable for machining materials such as common steel, non-ferrous metals, and cast iron, etc. It can process materials with hardness up to HRC 45.

Grade BT15: This grade is suitable for machining common steel, cast iron, stainless steel, heat-resistant steel, chilled hardened steel, nickel base alloy and titanium alloy, etc. It can process materials with hardness up to HRC 55.

Grade BT20: This grade is suitable for machining stainless steel, heat-resistant steel, chilled hardened steel, cast iron, nickel base alloy and titanium alloy, etc. It can process materials with hardness up to HRC 55.

Grade BT25: This grade is suitable for machining alloy steel, titanium alloy, chilled hardened steel cast iron, aluminium alloy, etc. It can process materials with hardness up to HRC 58.

Grade BT25UF: This grade is suitable for machining alloy steel, stainless steel, aluminium alloy, chilled hardened steel and titanium alloy, etc. It can process materials with hardness up to HRC 65.

Tungsten carbide drill bits sizes:

| Diameter(d) | Flute Length(L1) | Shank Diameter(D) | Shank Length(L2) | Overall Length L |

| 3.0-3.9 | 70 | 4 | 50 | 120 |

| 4.0-5.0 | 80 | 5 | 40 | 120 |

| 5.1-6.0 | 80 | 6 | 40 | 120 |

| 6.1-7.0 | 80 | 7 | 40 | 120 |

| 7.1-8.0 | 80 | 8 | 40 | 120 |

| 8.1-9.0 | 80 | 9 | 40 | 120 |

| 9.1-10.0 | 80 | 10 | 40 | 120 |

| 10.1-11.0 | 80 | 11 | 40 | 120 |

| 11.1-12.0 | 80 | 12 | 40 | 120 |

| 12.1-13.0 | 80 | 13 | 40 | 120 |

| 13.1-14.0 | 80 | 14 | 40 | 120 |

| 14.1-15.0 | 80 | 15 | 40 | 120 |

| 15.1-16.0 | 80 | 16 | 40 | 120 |

| 16.1-17.0 | 80 | 17 | 40 | 120 |

| 17.1-18.0 | 80 | 18 | 40 | 120 |

| 18.1-19.0 | 80 | 19 | 40 | 120 |

| 19.1-20.0 | 80 | 20 | 40 | 120 |

| 4.0-5.0 | 110 | 5 | 40 | 150 |

| 5.1-6.0 | 110 | 6 | 40 | 150 |

| 6.1-7.0 | 110 | 7 | 40 | 150 |

| 7.1-8.0 | 110 | 8 | 40 | 150 |

| 8.1-9.0 | 110 | 9 | 40 | 150 |

| 9.1-10.0 | 110 | 10 | 40 | 150 |

| 10.1-11.0 | 110 | 11 | 40 | 150 |

| 11.1-12.0 | 110 | 12 | 40 | 150 |

| 12.1-13.0 | 110 | 13 | 40 | 150 |

| 13.1-14.0 | 110 | 14 | 40 | 150 |

| 14.1-15.0 | 110 | 15 | 40 | 150 |

| 15.1-16.0 | 110 | 16 | 40 | 150 |

| 16.1-17.0 | 110 | 17 | 40 | 150 |

| 17.1-18.0 | 110 | 18 | 40 | 150 |

| 18.1-19.0 | 110 | 19 | 40 | 150 |

| 19.1-20.0 | 110 | 20 | 40 | 150 |

Our company supports customization of drill bit size and shape, welcome to send us drawings.

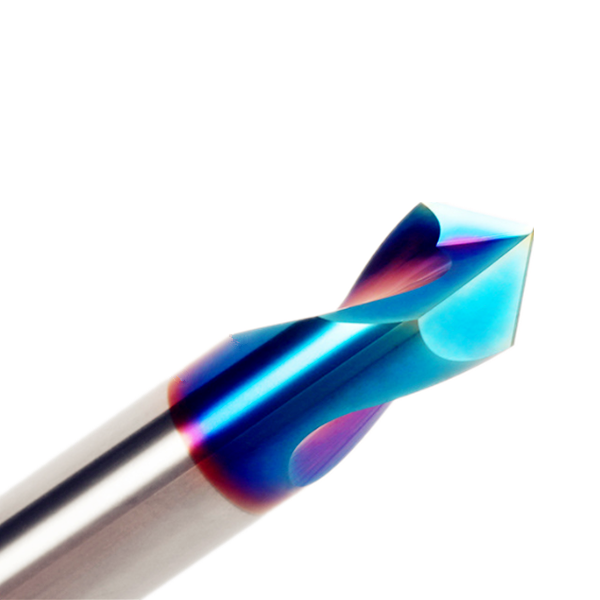

Tungsten carbide drill bits details:

Compatible Machine Tools:

Please send us inquiries for quotations and free samples for testing: