Carbide Anvils Usage Precautions and Maintenance Specifications

I. Preprocessing and Installation Specifications

Tungsten Carbide Anvils Quality Pre-inspection And Internal Stress Elimination.

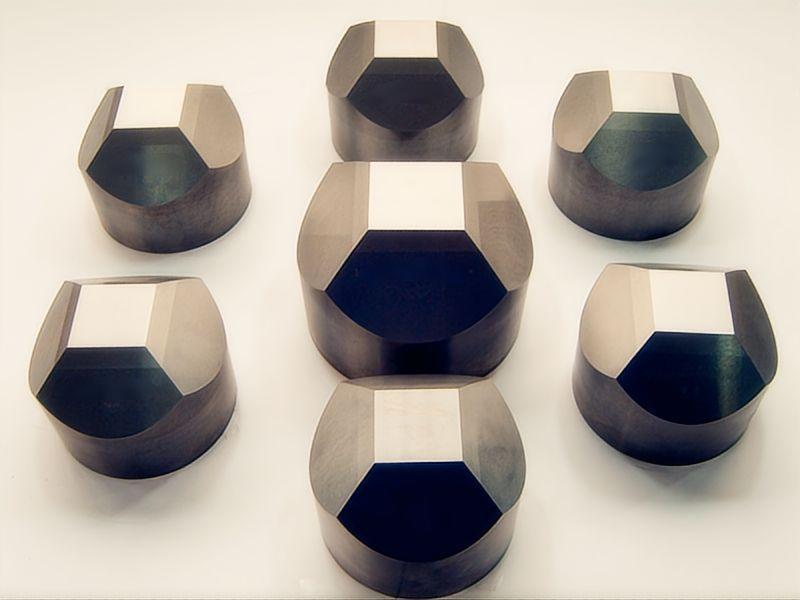

Prior to use, tungsten carbide anvils must undergo non-destructive testing (e.g., ultrasonic flaw detection) to inspect for internal defects such as cracks or porosity. Surfaces must be free of scratches, edge chipping, or oxidation layers, ensuring compressive strength and toughness meet process requirements (typically using hard alloy grades such as YG8, YG10, BTN8, and BTN10, hardness ≥ HRA89).

Measure flatness, parallelism, and dimensional accuracy of the tungsten carbide anvil working surface. Tolerances must be controlled within 0.01 mm to prevent localized stress concentration due to uneven force distribution.

Internal stress elimination treatment: Residual stresses from precision machining must be relieved via aging treatment before use. Methods include natural aging (≥1 month), oven aging (temperature ≤250°C, duration ≥72 hours), oil boiling aging, vacuum aging, or ultrasonic aging to reduce deformation or cracking risks.

Installation Positioning Accuracy and Assembly Requirements

tungsten carbide anvil assembly with cylinders and cushion blocks must be strictly concentric, ensuring the central axes of all four/six tungsten carbide anvil working surfaces coincide (deviation ≤0.05 mm). Misalignment causes uneven pressure distribution in the synthesis chamber, leading to “biased wear” or premature fracture.

Taper and press-fit: tungsten carbide anvil and steel ring tapers must match, with ≥90% contact area. Press-fit height must be appropriate: typically 8–10 mm for tungsten carbide anvils <Ф127 mm, 10–12 mm for ≥Ф127 mm.

Tungsten carbide anvils and cushion blocks must fit tightly with full surface contact; point contact is strictly prohibited to avoid stress concentration. Use specialized tooling during installation to prevent impact damage (hard alloy brittleness makes minor impacts prone to hidden cracks).

Surface Lubrication and Protection

Apply high-temperature, high-pressure lubricant (e.g., molybdenum disulfide-based grease) to the tungsten carbide anvil working surface to reduce friction wear against synthesis media (e.g., pyrophyllite, graphite) and prevent sintering adhesion.

Non-working surfaces may be coated with wear-resistant layers (e.g., TiN) to enhance corrosion and oxidation resistance. Protect against rust in humid environments.

II. Raw Material Quality Control

Core Component Precision Requirements.

Steel rings and cushion blocks must meet strict machining tolerances:

Steel ring inner wall roughness ≤ Ra1.6; roundness and taper must match tungsten carbide anvil geometric tolerances.

Cushion block parallelism ≤0.02 mm; hardness must be moderate (excessive hardness causes impact damage; insufficient hardness compromises force transmission).

Conductive steel rings must be rust-free and crack-free, with no blue brittleness after baking. Store in dry conditions to prevent oxidation-induced conductivity loss.

Synthesis Media Performance Assurance

Pyrophyllite must be calcined under controlled temperature and duration to ensure stable pressure transmission. Dry to moisture content ≤0.5% to prevent “blowouts” or gas explosions.

Particle size must be uniform (200–300 mesh) to avoid coarse impurities causing “point contact” wear on tungsten carbide anvil surfaces.

III. Synthesis Process Parameter Control

Pressure-Temperature Matching.

Strictly adhere to process parameters: pressure (typically 5–6 GPa) and temperature (1300–1600°C). Overpressure or overtemperature reduces tungsten carbide anvil service life by >50% due to grain growth and hardness degradation.

Pressure ramp rate must be steady (recommended ≤0.5 GPa/min) to prevent dynamic stress cracks. Depressurize slowly; hold ≥1 minute before cooling to avoid gas explosions.

Stability During Insulation and Pressure Holding

Monitor real-time pressure (fluctuation ≤±0.1 GPa) and temperature (fluctuation ≤±20°C). Excessive fluctuations cause fatigue failure from cyclic stress.

Optimize pressure-holding duration: prolonged exposure accelerates surface oxidation; insufficient time compromises diamond quality and increases tungsten carbide anvil reuse frequency.

IV. Equipment Foundation Assurance

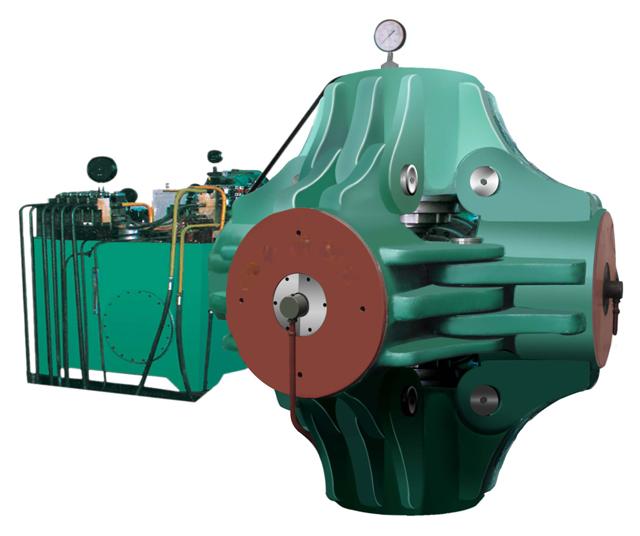

Presses must maintain high precision: synchronization and concentricity deviations ≤0.2 mm, zero leakage. Machine stability prevents uneven tungsten carbide anvil loading and abnormal wear.

Regularly calibrate pressure sensors, displacement sensors, etc., to prevent tungsten carbide anvil overload from equipment errors.

V. Cooling System Assurance

Cooling Circuit Integrity.

Clean internal cooling circuits every 50 synthesis cycles to remove scale and debris. Ensure flow rate ≥5 L/min, inlet temperature ≤30°C, outlet temperature ≤50°C. Inadequate cooling reduces tungsten carbide anvil surface hardness by >30% (at >300°C), causing plastic deformation.

Verify circuit sealing before installation to prevent leaks that cause insulation failure or electrochemical corrosion.

Cooling Method Selection

Small tungsten carbide anvils (diameter <50 mm): single-loop water cooling.

Large tungsten carbide anvils (diameter ≥80 mm): dual-loop cooling for uniform heat dissipation.

VI. Operation and Maintenance Protocols

Handling And Assembly Prohibitions.

During assembly:

Inspect pyrophyllite blocks for cracks/impurities; verify correct orientation of steel shims.

Clean all six tungsten carbide anvil surfaces before loading to prevent jams or electrical arcing.

Pre-synthesis check: Scratch-test all four tungsten carbide anvil surfaces to detect hidden defects and prevent blowouts.

Handle synthesis materials gently; avoid tool contact with tungsten carbide anvil surfaces. Never strike tungsten carbide anvil edges. Cool tungsten carbide anvils to <50°C before disassembly to prevent thermal cracking.

Operational Monitoring During Synthesis

During idle advance: Verify cylinder actions—stationary cylinders must not drift; moving cylinders must pause correctly at position.

Immediately halt upon abnormal noise or vibration.

Regular Inspection and Maintenance

After every 100 cycles:

Measure tungsten carbide anvil working surface wear. Grind to restore flatness if unilateral wear >0.5 mm (grinding depth ≤0.2 mm/session; excessive removal risks stress relief).

Inspect sides for “bulging” or cracks (common in stress zones); remove defective tungsten carbide anvils immediately.

Storage and Preservation

Store idle tungsten carbide anvils on vibration-free racks in dry conditions. Avoid stacking or metal-to-metal contact. Apply rust inhibitor and cover with dust-proof cloth.

Re-test hardness and surface condition after >3 months of storage.

VII. Safety Monitoring and Emergency Response

Real-Time Condition Monitoring.

Monitor tungsten carbide anvils via pressure sensors and infrared thermometers. Halt immediately upon abnormal pressure/temperature spikes or noise.

Install fracture pre-warning systems (e.g., vibration sensors) to trigger alarms upon abnormal frequencies.

Emergency Measures

Minor cracks: Withdraw tungsten carbide anvil, mark defect location, and isolate. Do not reuse or repair.

Shattered tungsten carbide anvil: Remove all fragments; inspect cylinder and components for damage. Replace all tungsten carbide anvils and conduct no-load test (80% operating pressure) before resuming production.

VIII. Process Matching and Life cycle Management

Select Tungsten Carbide Anvil Size And Material Based On Diamond Specifications.

Large diamonds (≥5 mm): Use high-toughness tungsten carbide anvils (e.g., YG10) with reduced pressure fluctuations.

Fine-grain diamonds: Use high-hardness tungsten carbide anvils (e.g., YG8) for extended wear life.

Maintain tungsten carbide anvil life cycle logs (usage count, repairs, failure modes). Optimize parameters (e.g., reduce high-pressure dwell time). Typical service life: 5,000–8,000 cycles. Exceeding this increases safety risks.

Implementation of these protocols extends hard alloy anvil service life by 30%–50%, reduces production failures, and ensures stable, safe diamond synthesis.

Our company is among China’s top ten tungsten carbide anvils manufacturers. Should you require cemented carbide products, please contact us.