Карбид вольфрама кровать ножи класса:

| Класс | WC(%) | Co(%) | Твердость(HRA) | TRS (Mpa) |

| BU03 | 97 | 3 | ≥94.5 | 3500 |

| BU06 | 94 | 6 | ≥94.5 | 3600 |

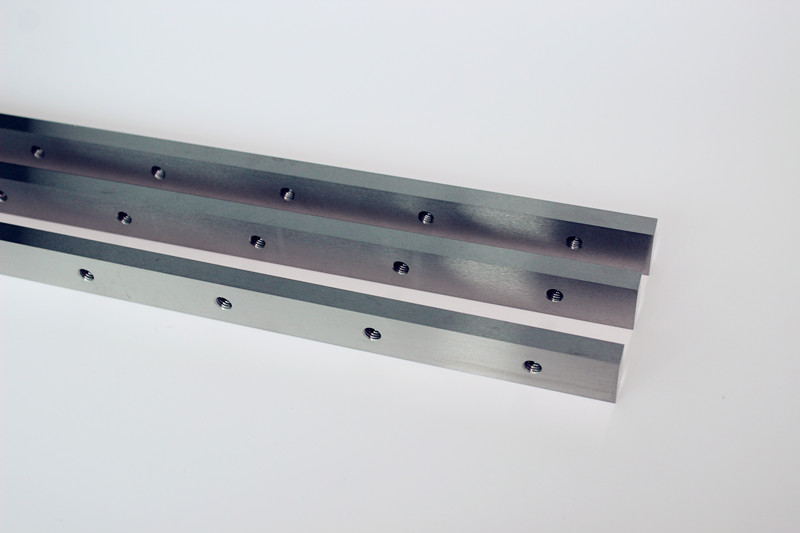

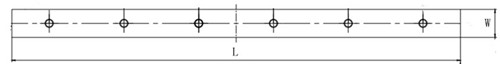

Размеры ножей из карбида вольфрама:

| L(MM) | W(MM) | H(MM) |

| 150 | 14 | 8 |

| 200 | 30 | 10 |

| 230 | 20 | 8 |

| 305 | 20 | 8 |

| 305 | 20 | 9.5 |

| 318 | 20 | 8 |

| 340 | 20 | 8 |

| 350 | 20 | 8 |

Мы поддерживаем изготовление на заказ, пожалуйста, предоставьте нам чертежи.

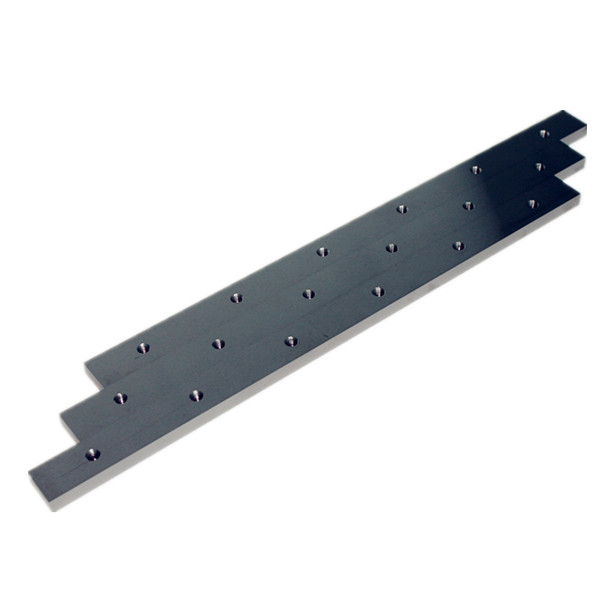

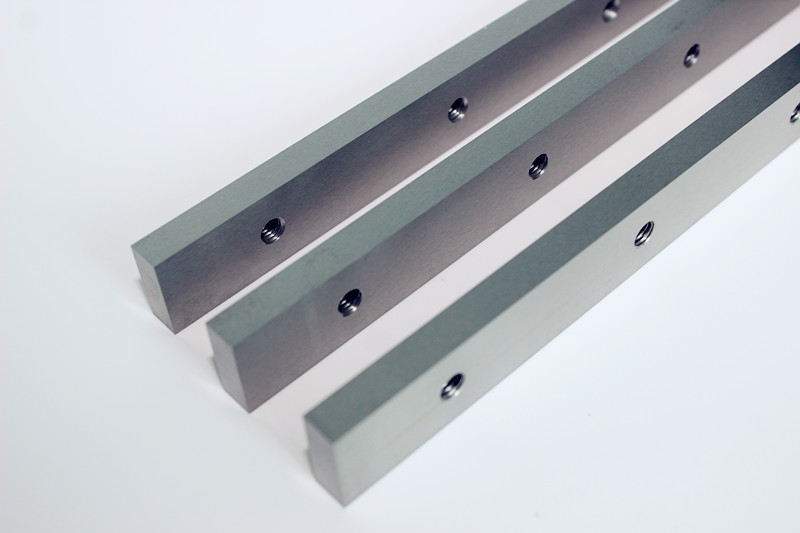

Детали ножей с твердосплавными станинами:

Преимущества ножа из твердого сплава:

1.непревзойденная износостойкость

Это самое заметное преимущество цементированного карбида. Его твердость намного выше, чем у любой другой инструментальной стали (HRA может достигать около 93, что значительно превышает твердость стали HRC 60). При резке высокоабразивных материалов (таких как армированные стекловолокном пластики, углеродные волокна и высоконаполненные материалы) срок его службы может в десятки и даже сотни раз превышать срок службы обычных стальных резцов. Это значительно сокращает частоту замены ножей и время простоя.

2. Чрезвычайно долгий срок службы

Это напрямую связано с его чрезвычайно высокой износостойкостью. Хотя первоначальные затраты на покупку высоки, его чрезвычайно долгий срок службы означает снижение затрат на процесс и повышение производительности, что в конечном итоге более экономично в долгосрочной перспективе.

3. Отличная прочность на сжатие

Цементированный карбид противостоит деформации под действием экстремального давления и сохраняет чрезвычайно высокую стабильность размеров, обеспечивая точные зазоры при резании и стабильное качество реза.

4. Умеренная коррозионная стойкость

Его химическая стабильность превосходит химическую стабильность обычной инструментальной стали, что делает его более устойчивым к коррозии под воздействием некоторых пластиковых добавок или химических веществ в среде обработки.

Пожалуйста, присылайте нам запросы для получения расценок и бесплатных образцов для тестирования: