Tungsten carbide sheets grades:

| Grade | Composition (%) | Density (g/cm3) | Hardness (HRA) | T.R.S (N/mm²) |

| YG6A / K05 / C2 | 6%co 94%wc | 14.85 | ≥92.5 | ≥2000 |

| YG8 /K30 / C6 | 8%co 92%wc | 14.7 | ≥89.8 | ≥2800 |

| YG10X / K30 / C7 | 10%co 90%wc | 14.35 | ≥91.5 | ≥3600 |

| YG11 / K30 / C8 | 11%co 89%wc | 14.4 | ≥88.5 | ≥2900 |

| YG15 / K30 / C9 | 15%co 85%wc | 14 | ≥87.0 | ≥3000 |

| YG20 / K40 / C10 | 20%co 80%wc | 13.5 | ≥85.5 | ≥2800 |

| YG13X / K30 / C8-C9 | 13%co 87%wc | 14.2 | ≥90.0 | ≥3200 |

| BT15 / K30 / C7 | 10%co 90%wc | 14.35 | ≥92.2 | ≥3900 |

| YG6A | Fine grain alloy, good wear resistance. It is suitable for manufacturing forming cutter, wear-resistant parts etc. |

| YG8 |

High bending strength, wear resistance lower than YG6A, suitable for manufacturing forming cutter, wear-resistant parts etc. |

| YG11 | |

| YG15 | Suitable for manufacturing punching dies, wear-resistant parts etc. |

| YG20 |

High bending strength, suitable for manufacturing progressive dies and other punching dies. |

| YG13X | |

| BT15 | Ultra-fine grain size, High performance, making cutting tools, suitable for cutting ordinary alloy steel, aluminum alloy, heat resistant alloy, cast iron, etc. |

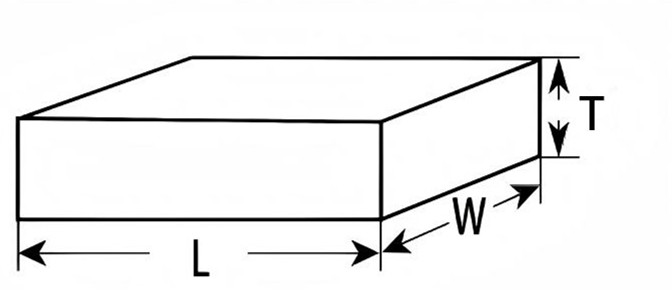

Tungsten carbide sheets sizes:

| Length (mm) (L) |

Tolerance | Width (mm) (W) |

Tolerance | Thickness (mm) (T) |

Tolerance |

| 100 | +2.0/0 | 100 | +2.0/0 | 1.0-70.0 | +0.5/+0.2 |

| 105 | +2.0/0 | 105 | +2.0/0 | 1.0-70.0 | +0.6/+0.2 |

| 110 | +2.0/0 | 110 | +2.0/0 | 1.0-70.0 | +0.8/+0.2 |

| 120 | +2.0/0 | 120 | +2.0/0 | 1.0-70.0 | +1.0/+0.2 |

| 135 | +2.0/0 | 135 | +2.0/0 | 1.0-70.0 | +1.2/+0.2 |

| 150 | +2.5/0 | 150 | +2.5/0 | 1.0-70.0 | +1.2/+0.2 |

| 200 | +2.5/0 | 200 | +2.5/0 | 3.0-70.0 | +1.2/+0.2 |

| 250 | +5.0/0 | 250 | +5.0/0 | 15.0-60.0 | +1.2/+0.2 |

| 300 | +7.0/0 | 300 | +7.0/0 | 20.0-60.0 | +1.2/+0.2 |

Carbide sheets details:

Please send us inquiries for quotations and free samples for testing: