Grades of tungsten carbide disc blanks:

| Grade | Density(g/cm3) | Hardness(HRA) | TRS(Mpa) |

| YG6X | 14.9 | ≥92.5 | 2400 |

| YG6 | 14.7 | ≥90.0 | 2400 |

| YG8 | 14.7 | ≥89.5 | 2800 |

| YG10X | 14.35 | ≥91.8 | 3600 |

| YS2T | 14.3 | ≥92.0 | 2500 |

| YG13X | 14.2 | ≥90.0 | 3200 |

| YG6X | Fine grain alloy, good wear resistance. It is suitable for semi-finishing the chilled cast iron, nonferrous metal and its alloy. It is also suitable for semi-finishing and finishing the hardened steel and alloy steel. |

| YG6 | High toughness. It is suitable for rough machining cast iron, non-ferrous metal and its alloy as well as non-metallic materials at low cutting speed. |

| YG8 | High toughness. It is suitable for rough machining cast iron, non-ferrous metal and its alloy as well as non-metallic materials at low cutting speed. |

| YG10X | Fine grain alloy, with good wear resistance. It is suitable for machining hardwood, plywood, PCB, PVC and metals. |

| YS2T | Fine grain alloy, with high wear resistance, bending strength, bonding resistance and thermal strength. It is suitable for machining plywood, PCB, PVC, refractory alloys, stainless steel and high manganese steel, etc. |

| YG13X | Moderate wear resistance and bending strength. It is suitable for machining steel alloy etc. |

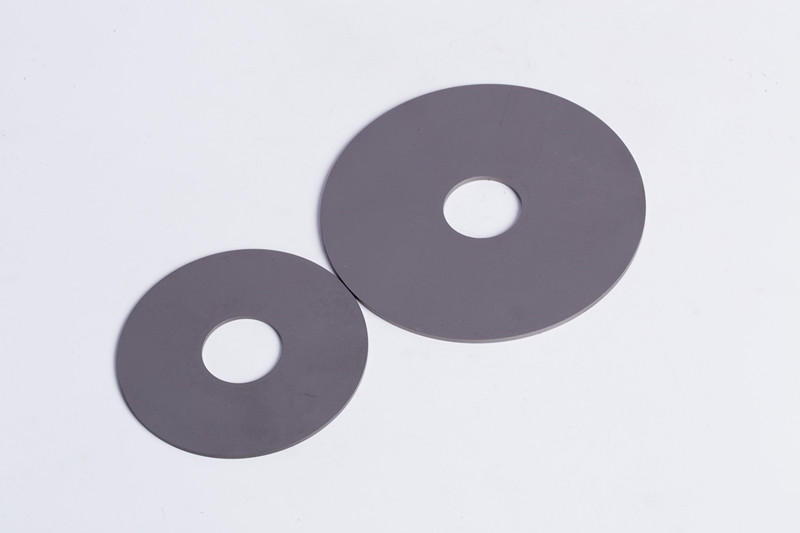

Sizes of tungsten carbide disc blanks:

| Type | OD(mm) | ID(mm) | Thickness(mm) |

| φ12×φ6×s | 12 | 6 | 0.6-4.5 |

| φ13×φ6×S | 13 | 6 | 0.6-4.5 |

| φ16×φ6×s | 16 | 6 | 0.6-4.5 |

| φ22×φ10×s | 22 | 10 | 0.6-4.5 |

| φ25×φ12×s | 25 | 12 | 0.6-4.5 |

| φ32×φ10×s | 32 | 10 | 0.8-5.5 |

| φ40×φ10×s | 40 | 10 | 0.8-6.0 |

| φ45×φ13×s | 45 | 13 | 0.8-6.0 |

| φ52×φ24.5×S | 52 | 24.5 | 0.8-6.0 |

| φ53×φ12×s | 53 | 12 | 0.8-6.0 |

| φ53×φ24.5×s | 53 | 24.5 | 0.8-6.0 |

| φ55×φ16×s | 55 | 16 | 0.8-6.0 |

| φ58×φ22×s | 58 | 22 | 0.8-6.0 |

| φ60×φ19×s | 60 | 19 | 0.8-7.0 |

| φ63×φ17×S | 63 | 17u | 0.8-7.0 |

| φ70×φ22×s | 70 | 22 | 0.8-7.0 |

| φ75×φ22×S | 75 | 22 | 0.8-7.0 |

| φ80×φ22×s | 80 | 22 | 0.8-7.0 |

| φ83×φ21×s | 83 | 21 | 0.8-7.0 |

| φ86.5×φ21.5×s | 86.5 | 21.5 | 1.0-7.0 |

| φ90×φ22×s | 90 | 22 | 1.0-7.0 |

| φ100×φ22×s | 100 | 22 | 1.0-7.0 |

| φ125×φ22×s | 125 | 22 | 1.0-7.0 |

| φ200×φ70×s | 200 | 70 | 3.0-4.5 |

| φ250×φ70×s | 250 | 70 | 3.0-4.5 |

| φ250×φ160×s | 250 | 160 | 3.0-4.5 |

| φ250×φ92×s | 250 | 95 | 3.0-4.5 |

| φ310×φ193×s | 310 | 193 | 3.0-4.5 |

| φ310×φ198×S | 310 | 198 | 3.0-4.5 |

Custom sizing is also available. Please provide us with your specifications.

Details of carbide disc blanks:

Please send us inquiries for quotations and free samples for testing: