Carbide wear block grades:

| Grade | Co(%) | Density (g/cm³) |

Hardness (HRA) |

Average Grain Size (μm) |

TRS (N/mm²) |

| BK5 | 6 | 14.90 | 88.0 | 3-5 | 2300 |

| BK3 | 8 | 14.70 | 87.0 | 3-5 | 2400 |

| BK2 | 9 | 14.60 | 86.7 | 3-5 | 2450 |

| BK1 | 10 | 14.50 | 86.3 | 3-5 | 2500 |

| BK13 | 13 | 14.20 | 85.5 | 3-5 | 2700 |

| BK15 | 15 | 14.00 | 84.5 | 3-5 | 2900 |

| BCK13 | 13 | 14.20 | 85.0 | 4-7 | 2650 |

| YG11C | 11 | 14.40 | 86.5 | 2-3 | 2450 |

| YG13C | 12 | 14.30 | 86.0 | 2-3 | 2500 |

| YG15C | 14 | 14.10 | 85.5 | 2-3 | 2600 |

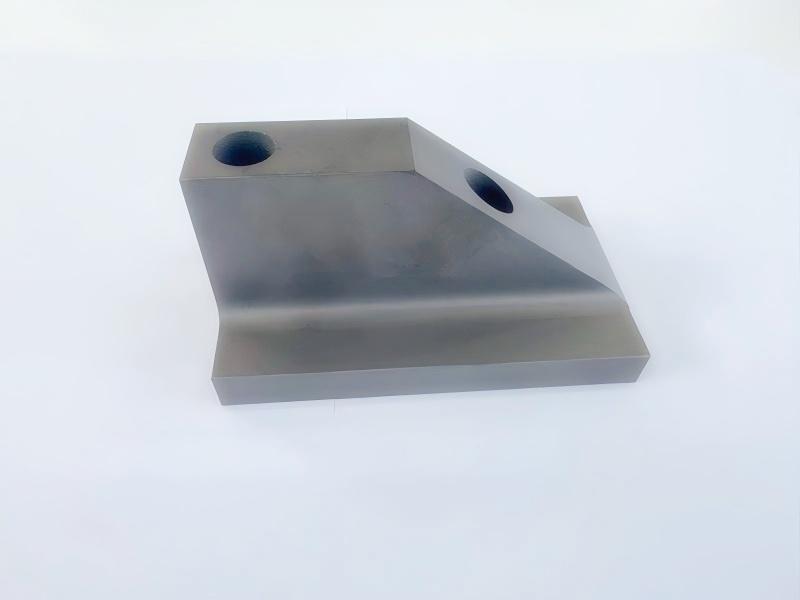

Carbide wear block details:

Carbide wear blocks applications:

- Protecting Vulnerable Parts of Construction and Mining Equipment:

1.1 Excavator Bucket: Welded onto the bucket’s lip plate, sidewalls, and bottom, especially around tooth adapters, to prevent rapid wear during excavation and loading of rock, gravel, and ore.

1.2 Loader Bucket: Installed on the bucket’s cutting edge, side edges, rear wall, and bottom to resist impact and abrasion from materials (e.g., crushed stone, ore, scrap steel).

1.3 Dozer Blade: Installed on the blade moldboard, end bits (sides), and corners to protect against severe wear from soil, rock, and rubble.

1.4 Motor Grader Blade: Installed on the blade bottom and cutting edge to resist abrasive wear during road construction and land leveling.

1.5 Scraper Bowl: Protects the bowl’s cutting edge, sidewalls, and floor. - Extending the Lifespan of Material Handling Equipment:

2.1 Chutes and Hoppers: Installed in areas subject to high-impact, flow, and friction from materials (e.g., ore, coal, sand, grain, recycled scrap) at impact points, bends, and bottoms. Examples: Feed chutes under mine crushers, sinter chutes, ship loader hoppers, critical transition points in grain conveying systems.

2.2 Screen Deck Beams and Side Plates: On vibrating screens, beams and side plates endure continuous material impact and abrasion. Wear blocks can be welded onto these parts to reduce wear and extend screen frame life.

2.3 Mixer/Blender Liners: In equipment mixing abrasive materials (e.g., concrete aggregate, mineral slurry), welded onto high-wear areas of mixing arms, blades, or drum walls.

2.4 Screw Conveyor Flight Edges: Protects the edges of flights from wear during the conveying of abrasive materials. - Enhancing Wear Resistance in Mine Crushing and Grinding Equipment:

3.1 Jaw Crusher: Installed on specific high-wear areas of the moving jaw and fixed jaw plates as an additional protective layer.

3.2 Cone Crusher/Gyratory Crusher: Installed on the support ring or specific areas of the mantle (moving cone) and concave (fixed cone).

3.3 Impact Crusher: Installed on high-impact wear areas such as rotor blow bars, impact aprons/rear plates, and feed guides.

3.4 Hammer Crusher: Installed on shell liners, breaker plates (impact plates), and other parts subjected to repeated impact from material and hammers.

3.5 Ball Mill/Semi-Autogenous Grinding (SAG) Mill: Installed at key wear points like feed end liners, mill shell liner lifters, and discharge grates. While large liners themselves may be made of high-chromium cast iron or alloy steel, hard alloy blocks are often embedded at extreme wear points for enhanced wear resistance. - Protecting Agricultural Machinery:

4.1 Plowshares and Moldboards: Installed on the share point and moldboard wing, the parts in direct contact with soil and stones experiencing the most severe wear.

4.2 Planter Openers: Protects the edges and sides of opener discs or tines.

4.3 Combine Harvester Header: Installed on vulnerable wear points like divider points, cutterbar guards, and feederhouse floors.

4.4 Subsoiler Points: Welded onto the working surface of the point to resist soil abrasion. - Other Industrial Applications:

5.1 Recycling Industry: Inside equipment (e.g., shredders, crushers) processing scrap metal, construction debris, e-waste, to resist wear from extremely hard materials.

5.2 Cement Industry: At high-wear points in raw material mills, clinker crushers, and conveying equipment.

5.3 Steel Industry: Blast furnace charging systems, sinter crushers and conveyors, certain guides and guards in continuous casting equipment.

5.4 Snow Removal Equipment: Installed on snowplow cutting edges and wing plates to resist wear from ice/snow mixtures and road grit/sand. - Shield tunneling machine / Tunnel Boring Machine.

In short: Hard alloy wear blocks are a vital solution for extending service life, ensuring operational efficiency, and improving the cost-effectiveness of key vulnerable parts in industrial equipment and machinery wherever severe abrasive wear, impact wear, or erosive wear occurs. They act as a “sacrificial” protective layer, safeguarding more expensive, larger, and harder-to-replace base components.

Our customer background for carbide blocks: We supply tungsten carbide blocks for China Railway Group (CREC),Vermeer, etc.

We support product customization. Please send us inquiries for quotations and free samples for testing: