Is tungsten carbide stronger than steel ?

Is tungsten carbide stronger than steel? The answer is yes. Tungsten carbide is significantly stronger than all types of steel. The hardness of tungsten carbide is usually 2 to 3 times that of high-quality alloy steel, and can even reach 4 times or more under certain measurement standards. As a professional tungsten carbide product manufacturer, I will compare the hardness and usage scenarios of tungsten carbide and steel by comparing their industrial applications. First, we can explain in detail from several aspects:

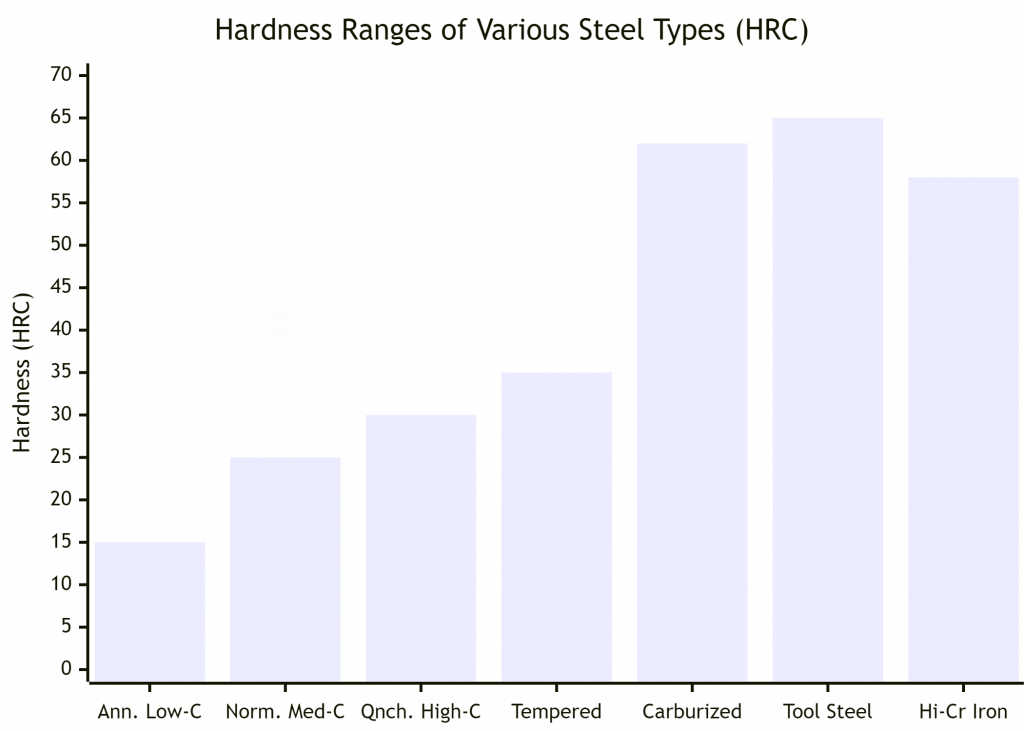

1. Direct Hardness Comparison:

Tungsten carbide (WC): Its hardness is typically between 8.5 and 9 on the Mohs scale, and its Vickers hardness (HV) can reach 1800HV or even higher.

Steel: Steel has a wide range of hardness, depending on its type and heat treatment.

Ordinary structural steel: Its hardness is very low, with a Vickers hardness of approximately 150-250 HV.

Hardened tool steel/die steel: This is the highest hardness level steel can achieve, with a Rockwell hardness (HRC) of approximately 60-68. Converted to a Vickers hardness of approximately 700-900 HV. High-Speed Steel (HSS): A high-performance tool steel with a hardness of 64-68 HRC (approximately 850-900 HV).

Conclusion: Even the hardest steel (~900 HV) is only about half as hard as tungsten carbide (~1800 HV). Tungsten carbide is two to three times harder than hardened high-carbon steel. Please see the bar chart below:

2. Why is tungsten carbide so hard?

This begins with its microstructure:

Steel: Primarily composed of iron (Fe), with carbon (C) and other alloying elements (such as chromium, molybdenum, and vanadium). Its high hardness comes primarily from the martensite structure formed after heat treatment (quenching). This is a metastable structure in which carbon atoms are supersaturated in the iron lattice, causing the lattice to distort, resulting in extremely hardness but also greater brittleness.

Tungsten Carbide: It is a cermet material composed of tungsten (W) and carbon (C) atoms bound together by extremely strong covalent bonds. The strength of these atomic bonds makes its crystal structure extremely stable and hard. The “tungsten carbide” products we commonly use (such as knives and drill bits) are actually a cemented carbide formed by sintering tungsten carbide particles (which provide hardness) with a metallic cobalt (Co) binder (which provides toughness). Even with the addition of cobalt, its overall hardness remains far greater than that of steel.

3. The Price of Hardness: Toughness (Brittleness):

Although tungsten carbide is extremely hard, it has a significant disadvantage: it is brittle and has poor toughness.

Steel: It has excellent toughness and can withstand bending, impact, and deformation without breaking. You can bend a good steel knife significantly and it will still bounce back.

Tungsten carbide: It is very brittle and tends to chip and shatter rather than bend when subjected to sharp impact or improper pressure. If you hit a tungsten carbide drill bit, it might chip.

It’s like comparing glass and plastic: glass (like tungsten carbide) is very hard and wear-resistant, but it shatters easily if dropped; plastic (like steel) is softer and easily scratched, but it’s difficult to break. Summary and Comparison Table

| Property | Tungsten Carbide (Hardmetal) | High-Strength Steel (e.g., Tool Steel) |

| Hardness | Extremely High (1800+ HV) | High (700-900 HV) |

| Toughness | Low (Brittle, prone to chipping) | High (Impact resistant, bendable) |

| Wear Resistance | Excellent | Good |

| Compressive Strength | Extremely High | High |

| Density | Very High (~15.63 g/cm³) | High (~7.85 g/cm³) |

| Primary Applications | Cutting tools, drill bits, molds, wear-resistant parts | Blades, springs, gears, structural components, tools |

Application Scenarios:

Choose tungsten carbide: When you require extremely high hardness, wear resistance, and durability, especially when machining other hard materials (such as steel, cast iron, or composite materials). Examples include:

Lathe tools for machine tools, milling inserts, drilling bits for mining, watch cases, luxury pen nibs (wear-resistant, non-fading), nail drill bits, and dental drill bits.

Choose steel: When you require a combination of properties—toughness, impact resistance, and machinability—while maintaining a certain level of hardness. Examples include:

Hammers, crowbars, springs, kitchen knives, swords, axes, automobile frames, bearings, gears, gear shafts, and equipment frameworks.

Tungsten carbide can replace steel in the following situations, thereby increasing workpiece life, reducing production costs, and improving productivity.

1. Metal Cutting Tools: Lathe tools, milling cutters, and drill bits

Replaced Steel Products: High-Speed Steel (HSS) tools. Specific Example:

When machining steel, cast iron, stainless steel, or even harder nickel-based alloys on CNC machining centers, high-speed steel drills or milling cutters can wear out and become dull after just a few dozen parts.

Alternative Solution: Replace the cutting edge of the tool with tungsten carbide inserts (indexable inserts) or use solid carbide drills/end mills.

Advantages:

Cutting Speed: Carbide allows for cutting speeds 4-8 times higher than high-speed steel, significantly improving production efficiency.

Lifespan: Tool life is extended by dozens or even hundreds of times, reducing tool changes and downtime.

Processing Quality: Dimensional accuracy and surface finish are better maintained.

2. Wire Drawing Dies

Replaced Steel Product: Tool Steel Dies.

Specific Example:

When producing copper, steel, and aluminum alloy wire, the wire is forcibly drawn through a hole called a “drawing die” to reduce its thickness. This process causes extreme wear and tear on the die’s inner bore.

Alternative Solution: Use carbide drawing dies. The die bore is typically made of polycrystalline diamond (PCD), but the die base is almost entirely carbide.

Advantages:

Wear Resistance: Hundreds of times longer lifespan than steel dies, ensuring dimensional stability and surface quality of the drawn wire.

Efficiency: Able to withstand higher drawing speeds and greater surface reduction.

3. Wear-Resistant Parts and Seals

Replaced Steel Products: Wear-resistant parts made of hardened steel and stainless steel.

Specific Example:

Mechanical seals in sand pumps: Used to pump liquids containing solid particles (such as sand, gravel, and slurry). These granular media can cause severe erosion and wear on the sealing surfaces. Steel seals have a very short lifespan.

Alternative: Use tungsten carbide (typically YG) for dynamic and static seals.

Advantages: Its extremely high wear resistance ensures long lifespan and sealing reliability under harsh operating conditions, significantly reducing maintenance costs and downtime.

4. Rollers

Replaced Steel Products: High-strength alloy steel rolls in cold rolling mills. Specific Example:

In the finishing train (pre-finishing and finishing stands) of a high-speed wire rod mill, the rolls are required to operate continuously under high stress and high temperature, resulting in rapid wear.

Alternative Solution: Use carbide rolls (typically tungsten carbide-based).

Advantages:

Wear Resistance: Longer-lasting life than steel rolls, reducing roll changes and improving mill availability.

Product Precision: Long-term maintenance of groove dimensions ensures high dimensional accuracy and consistent surface quality of the wire rod.

5. Mining Tools: Rock Drill Bits

Replaced Steel Products: Carburized steel or alloy steel drill bits.

Specific Example:

In oil and gas drilling and mining, drill bits used for percussive drilling (such as slotted and cross drill bits) directly collide and rub against hard rock.

Alternative Solution: Modern rock drill bits feature carbide teeth embedded in the cutting edge (typically YG type, which offers excellent impact resistance). Advantages:

Its hardness and wear resistance allow it to easily crush rock, while steel drill bits would quickly wear out and fail. This is one of the most successful and widespread examples of cemented carbide replacing steel.

Key Summary and Limitations:

Cemented carbide is not a panacea; its replacement is conditional:

Advantages: High hardness (HRA 82-94), good wear resistance, and high compressive strength.

Disadvantages: Brittleness, low bending strength, poor toughness, and high price.

Therefore, it cannot replace steel structures that must withstand significant impact, bending stress, or require overall toughness, such as automobile frames, machine bodies, and chassis.

Steel structures in bridges, springs, wrenches, and other tools.

The replacement of cemented carbide is essentially a trade-off of wear resistance for toughness. In areas where wear resistance is paramount, it perfectly replaces steel, bringing revolutionary progress.

In summary, tungsten carbide undeniably surpasses all steels in pure hardness. However, it is not without flaws; its brittleness limits its use in many applications requiring impact resistance. The two are important industrial materials with complementary properties.

Our company is among China’s top ten tungsten carbide products manufacturers. Should you require cemented carbide products, please contact us.