Grado de cuchillas de lecho de carburo de tungsteno:

| Grado | WC(%) | Co(%) | Dureza(HRA) | TRS(Mpa) |

| BU03 | 97 | 3 | ≥94.5 | 3500 |

| BU06 | 94 | 6 | ≥94.5 | 3600 |

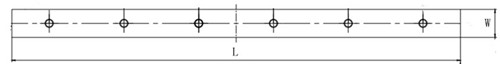

Cuchillas de lecho de carburo de tungsteno tamaños:

| L(MM) | W(MM) | H(MM) |

| 150 | 14 | 8 |

| 200 | 30 | 10 |

| 230 | 20 | 8 |

| 305 | 20 | 8 |

| 305 | 20 | 9.5 |

| 318 | 20 | 8 |

| 340 | 20 | 8 |

| 350 | 20 | 8 |

Apoyamos la personalización, por favor proporciónenos dibujos.

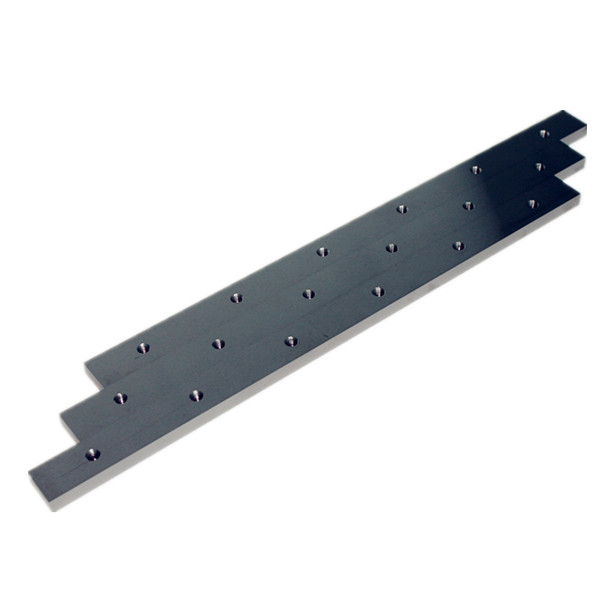

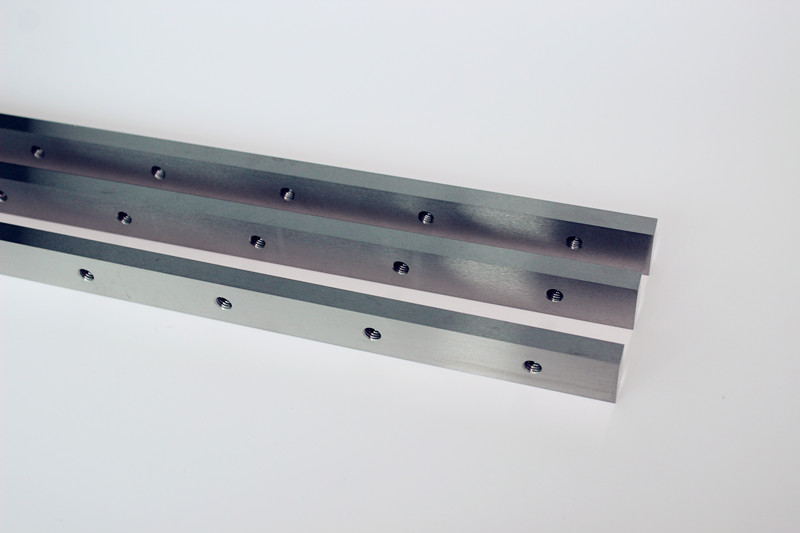

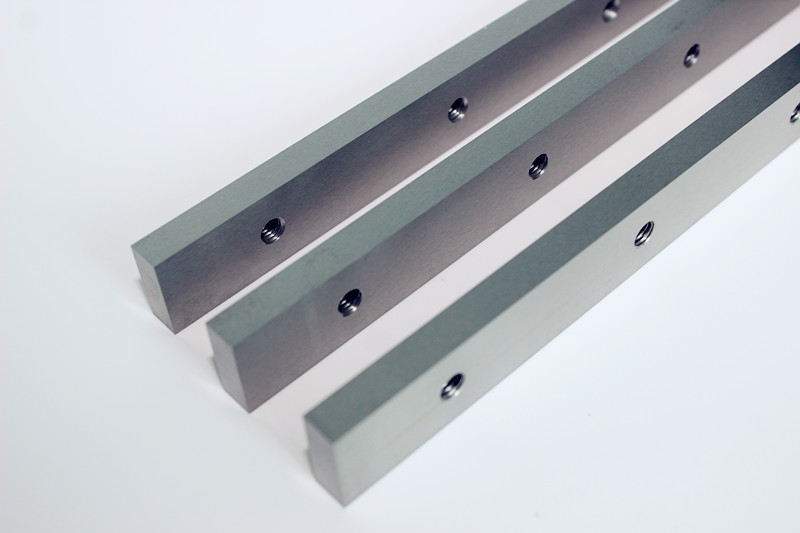

Detalles de los cuchillos de lecho de carburo:

Ventajas de las cuchillas de metal duro:

1.Resistencia al desgaste sin igual

Ésta es la ventaja más destacada del carburo cementado. Su dureza es muy superior a la de cualquier otro acero para herramientas (la HRA puede alcanzar alrededor de 93, superando con creces la del acero HRC 60). Al cortar materiales muy abrasivos (como plásticos reforzados con fibra de vidrio, fibras de carbono y materiales muy rellenos), su vida útil puede ser decenas o incluso cientos de veces superior a la de las fresas de lecho de acero ordinarias. Esto reduce significativamente la frecuencia de los cambios de cuchilla y los tiempos de inactividad.

2. Vida útil extremadamente larga

Esto se debe directamente a su altísima resistencia al desgaste. Aunque el coste de adquisición inicial es elevado, su vida útil extremadamente larga se traduce en menores costes por proceso y mayor productividad, lo que a la larga resulta más económico.

3. Excelente resistencia a la compresión

El carburo cementado resiste la deformación bajo presión extrema y mantiene una estabilidad dimensional extremadamente alta, lo que garantiza separaciones de corte precisas y una calidad de corte constante.

4. Resistencia moderada a la corrosión

Su estabilidad química supera a la del acero para herramientas ordinario, por lo que es más resistente a la corrosión provocada por determinados aditivos plásticos o productos químicos presentes en el entorno de mecanizado.

Envíenos sus consultas para obtener presupuestos y muestras gratuitas para pruebas: