Die zulässige Spannung von zementiertem Wolframkarbid

Gesintertes Wolframkarbid wird häufig in der Konstruktion verwendet, und die Kenntnis der zulässigen Spannung von Hartmetall hilft Ingenieuren bei der Auswahl geeigneter Materialien. Die zulässige Spannung bezieht sich auf die maximale Spannung, die ein Material langfristig sicher aushalten kann; ein Überschreiten dieses Wertes kann zu Verformungen oder Brüchen führen. Als repräsentative Hartlegierung wird die zulässige Spannung von Wolframkarbid durch Zusammensetzung, Temperatur, Verarbeitungstechniken und andere Faktoren beeinflusst. Spezifische Werte erfordern eine Analyse auf der Grundlage der tatsächlichen Bedingungen.

Sinterkarbid besteht aus Wolfram- und Kohlenstoffatomen und erreicht annähernd die Härte von natürlichem Diamant und weist eine außergewöhnliche Verschleißfestigkeit auf. Bei diesem Material wird häufig Kobalt als Bindemittelphase verwendet - ein höherer Kobaltgehalt verbessert die Zähigkeit, kann aber die Härte und die zulässige Spannung verringern. Sinterkarbid mit 6%-Kobalt beispielsweise hat in der Regel eine Druckfestigkeit zwischen 4.000 und 5.000 MPa, wobei für die praktisch zulässige Spannung ein Sicherheitsfaktor gilt, der in der Regel 1/5 bis 1/3 der Druckfestigkeit beträgt.

Die Temperatur hat einen erheblichen Einfluss auf die zulässige Spannung. Während es bei Raumtemperatur stabil ist, wird gesintertes Wolframkarbid oberhalb von 500°C weicher, wodurch die zulässige Spannung stark abfällt. Experimentelle Daten zeigen, dass die zulässige Spannung um etwa 8%-12% pro 100°C Temperaturerhöhung abnimmt. Hochtemperaturanwendungen erfordern eine sorgfältige Planung des Kühlsystems und der Temperaturüberwachung.

Die Herstellungsverfahren bestimmen unmittelbar die Leistungsfähigkeit des Werkstoffs. Durch Niederdrucksintern hergestelltes Wolframkarbid verringert die Porosität im Vergleich zu herkömmlichen Verfahren um 0,5%-1% und erhöht die zulässige Spannung um über 15%. Oberflächenbehandlungen wie CVD-Beschichtungen (chemische Gasphasenabscheidung) bilden eine 5-10 μm dicke Titannitridschicht, die die zulässige Oberflächenspannung um 20% erhöht, ohne die Zähigkeit zu beeinträchtigen.

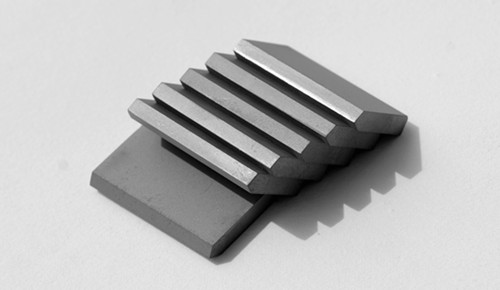

Bei praktischen Anwendungen muss die Spannungskonzentration berücksichtigt werden. Aufgrund der Sprödigkeit des Materials sollten scharfe Kanten bei der Konstruktion von Teilen vermieden werden. Ein Werkzeughersteller berichtete, dass eine Erhöhung des Schneidkantenradius von 0,1 mm auf 0,3 mm die Lebensdauer des Werkzeugs um das Dreifache erhöht. Die Kontrolle der Vorspannung bei der Montage ist ebenfalls von entscheidender Bedeutung, da übermäßige Spannungen zu Mikrorissen führen können.

Die zulässigen Spannungswerte variieren je nach Norm. ASTM B657 spezifiziert einen zulässigen Spannungsbereich von 800-1.200 MPa für industrielles Hartmetall, während DIN 4990 600-1.000 MPa für bestimmte Bedingungen vorsieht. Bei der Auswahl sollte das Anwendungsszenario berücksichtigt werden, z. B. niedrigere Werte für Stoßbelastungen und mittlere bis höhere Werte für statische Belastungen.

Die Wartung beeinflusst die Dauerhaftigkeit der zulässigen Belastung. Regelmäßige Kontrollen auf Oberflächenverschleiß sind unerlässlich; Abplatzungen von mehr als 0,2 mm können die Tragfähigkeit um 30% verringern. Auch die Wahl des Schmiermittels ist wichtig: Fett mit festem Schmiermittel kann die Kontaktbelastung im Vergleich zu Standardölen um 15%-20% verringern.

Die Materialprüfung ist entscheidend für die Gewährleistung der zulässigen Spannung. Die Ultraschallprüfung erkennt interne Defekte bis zu einer Größe von 0,1 mm, und die Röntgenbeugung analysiert die Eigenspannungsverteilung. Zerstörende Prüfungen - einschließlich Dreipunkt-Biege- und Druckprüfungen - sollten pro Charge durchgeführt werden, um die Einhaltung der Konstruktionsanforderungen zu überprüfen.

Eine technische Fallstudie zeigt, dass der Ersatz einer Getriebewelle in einer Bergbaumaschine durch Hartmetall die zulässige Spannung im Vergleich zur ursprünglichen Konstruktion um 50% erhöht hat, obwohl dies verbesserte Stützstrukturen erforderte. Durch diese Änderung verlängerte sich die Lebensdauer der Ausrüstung von 6 Monaten auf 3 Jahre, was die erheblichen Vorteile einer ordnungsgemäßen Anwendung der zulässigen Spannungsdaten verdeutlicht. Beachten Sie, dass Materialparameter niemals blind angewendet werden sollten; eine umfassende, auf die spezifischen Betriebsbedingungen zugeschnittene Analyse ist unerlässlich.