Carbide Hardness Characteristics And Industrial Applications

Carbides, as a class of critical engineering materials, are extensively and crucially utilized in numerous fields such as industrial manufacturing, aerospace, and electronic devices due to their exceptional hardness, wear resistance, and high-temperature stability. This article provides a systematic analysis of the hardness characteristics, typical products, and application areas of five major carbides (tungsten carbide, titanium carbide, silicon carbide, vanadium carbide, and chromium carbide), aiming to offer valuable reference for material selection and engineering design.

Characteristics and Applications of Tungsten Carbide (WC)

Tungsten carbide is one of the hardest known carbides, with a Vickers hardness ranging from 2200 to 2400 HV and a Mohs hardness equivalent of 9 to 9.5. This extreme hardness originates from the strong covalent bonds formed between tungsten and carbon atoms within its hexagonal close-packed crystal structure. This structural characteristic enables tungsten carbide to resist deformation and wear effectively under external forces.

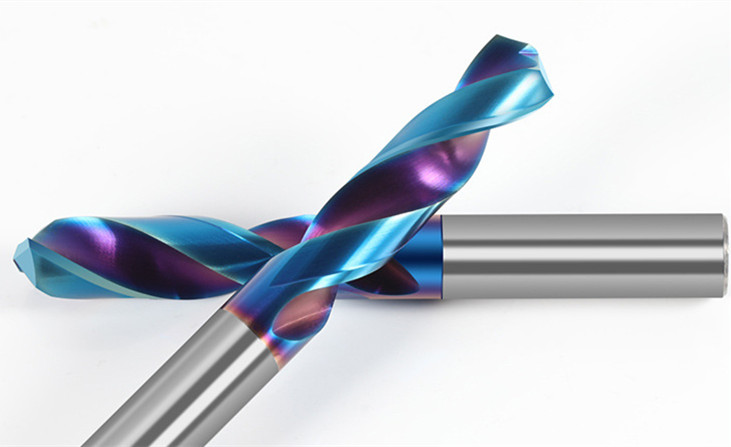

In terms of applications, tungsten carbide performs outstandingly. In the cutting tool sector, as the primary component of cemented carbides, it is widely used to manufacture high-precision cutting tools such as turning tools tungsten carbide inserts, milling cutters, and tungsten carbide drill bits. These tools can effortlessly handle the machining of various metal materials, ensuring processing accuracy and efficiency. For wear-resistant components, it is commonly employed in producing liner plates for mining machinery and petroleum drilling tools, significantly extending the service life of such equipment. In the electronics sector, nano-tungsten carbide powder is used in cemented carbide production, wear-resistant coatings, and high-temperature component manufacturing, expanding its applications in high-tech fields.

Representative products are diverse, including tungsten steel plates sized 150×150×3 mm, suitable for manufacturing various wear-resistant structural components; YG10X cemented carbide nails and other cutting tools that play vital roles in metal machining; and cast tungsten carbide welding rods, primarily used for hardfacing petroleum drilling tools to enhance their wear resistance.

Hardness Characteristics and Industrial Value of Titanium Carbide (TiC)

Titanium carbide demonstrates exceptional hardness properties, with a Vickers hardness of 2800–3000 HV (equivalent to 27–30 GPa) and a Mohs hardness of 9–10. This high hardness, combined with good chemical stability, makes it an indispensable engineering material in the industrial sector.

Titanium carbide finds broad application directions. In cutting tools, as an additive in WC-Co cemented carbides, it enhances the tool’s impact resistance and service life, making it more durable in complex cutting environments. In electronic materials, MXene materials (Ti₃C₂Tₓ), derived from titanium carbide, are used in nano-adsorption, biosensors, and energy storage devices, injecting new vitality into the electronics industry. For wear-resistant coatings, it is applied in surface treatments of mechanical parts, significantly improving their wear and corrosion resistance and reducing component degradation.

Typical industrial products include 50 nm titanium carbide powder with 99.9% purity, providing high-quality raw materials for advanced material preparation; titanium carbide particle reinforcements used in aerospace engine turbine disks, enhancing their high-temperature strength and wear resistance; and high-purity titanium carbide coating materials, ensuring coating quality and performance.

Unique Properties and Application Prospects of Silicon Carbide (SiC)

Silicon carbide is renowned for its ultra-high hardness and excellent thermal stability, with a Vickers hardness range of 2500–3000 HV and a Mohs hardness of 9.0–9.5. Both its hexagonal crystal structure (α-SiC) and cubic crystal structure (β-SiC) exhibit outstanding mechanical properties, maintaining good hardness and stability under both room temperature and high-temperature conditions.

In core application areas, silicon carbide also performs impressively. In semiconductor devices, it is used to manufacture high-performance SiC-based power devices (e.g., MOSFETs, diodes), widely applied in electric vehicles and power grids to improve energy conversion efficiency and device reliability. For high-temperature structural materials, it is commonly used in aerospace engine components and nuclear reactor structures, capable of withstanding extreme temperatures and complex operating conditions. In abrasives and grinding tools, it serves as an emery material for machining metals and ceramics, offering excellent grinding effect and high efficiency.

Representative products include 1700V silicon carbide power modules (HPD package), providing robust power support for power electronic equipment; silicon carbide fibers used in aerospace composites, enhancing the strength and high-temperature resistance of composite materials; and silicon carbide ceramics, applicable in high-temperature furnaces and catalyst carriers, leveraging their high-temperature resistance and chemical stability.

Hardness Characteristics and Multifunctional Applications of Vanadium Carbide (VC)

Vanadium carbide possesses extremely high hardness and melting point, with a Vickers hardness of 2800–2944 HV (under a 50g load), a Mohs hardness of 9–9.5, and a melting point exceeding 2800°C. Its sodium chloride-type cubic crystal structure (lattice constant 4.182 Å) confers stable mechanical properties, enabling it to maintain good performance under various harsh conditions.

The primary uses of vanadium carbide span multiple fields. As an additive in cemented carbides, it acts as a grain growth inhibitor, effectively preventing WC grains from coarsening during sintering, ensuring a uniform microstructure of the cemented carbide, and improving the material’s strength and hardness. In steel metallurgy, adding vanadium carbide enhances the wear resistance, corrosion resistance, and thermal fatigue resistance of steel, improving its overall performance. In new energy materials, it can serve as an anode material for lithium-ion batteries and a component in supercapacitors, boosting energy storage performance and cycle life.

Typical product forms include nano-vanadium carbide powder (1–2 μm, purity ≥99%), meeting the demands of high-precision material preparation; vanadium carbide coating materials for surface strengthening of parts; and high-purity vanadium carbide ingots (99.9%), providing raw materials for advanced material research and development.

Performance Characteristics and Engineering Applications of Chromium Carbide (Cr₃C₂)

Chromium carbide exhibits good comprehensive properties, with a Vickers hardness of 1800 HV and a thermal expansion coefficient of 10.3×10⁻⁶/K. Its orthorhombic crystal structure (a=2.821, b=5.52, c=11.46 Å) and density of 6.68 g/cm³ make it highly suitable for high-temperature applications.

In terms of application scenarios, chromium carbide is widely used in wear-resistant coatings. Relevant technologies are often employed to coat it onto the surface of steel materials, improving their wear resistance under harsh conditions such as high temperatures and corrosion, for example, spraying chromium carbide coatings on boiler pipes and heat exchanger surfaces. For high-temperature structural materials, it can be used to manufacture aerospace engine components and industrial kiln linings, enduring high-temperature environments. In cutting tools, as a component of cemented carbides, it enhances tool life, ensuring smooth cutting operations.

Typical industrial products include chromium carbide ceramics with a theoretical density of 6.68 g/cm³, suitable for various high-temperature wear-resistant components; ultrafine chromium carbide powder (1–2 μm, 99.9% purity), guaranteeing the preparation of high-quality coatings and ceramic materials; and chromium carbide coatings with a hardness of HV1700–2000, effectively improving surface properties of components.

Carbide Hardness Comparison and Selection Guide

| Carbide type | Vickers (HV) | Mohs Hardness | Melting point (℃) | Main Features |

| Tungsten carbide (WC) | 2200-2400 | 9-9.5 | 2870 | High hardness, outstanding wear resistance. |

| Titanium carbide (TiC) | 2800-3000 | 9-10 | 3140 | High hardness, Good chemical stability. |

| Silicon carbide (SiC) | 2500-3000 | 9-9.5 | 2700 | High thermal stability, semiconductor properties. |

| Vanadium carbide (VC) | 2800-2944 | 9-9.5 | 2810 | High melting point, good catalytic performance. |

| Chromium carbide (Cr₃C₂) | 1200-1800 | 8-9 | 1890 | Medium hardness, good oxidation resistance. |

In practical applications, the hardness performance of carbides is influenced by various factors. In terms of crystal structure, cubic carbides (e.g., TiC, VC) generally exhibit higher hardness stability than hexagonal ones, related to the symmetry and bonding forces within the crystal lattice. Regarding purity, materials prepared from high-purity (≥99.9%) carbide powders demonstrate higher hardness and more stable performance, as impurities can disrupt the integrity of the crystal structure and reduce material hardness. In preparation processes, nanostructured carbides (particle size 50–200 nm) can significantly enhance the hardness and toughness of composite materials, with the small size effect of nanoparticles optimizing material properties. Concerning temperature, most carbides maintain relatively high hardness at elevated temperatures, but prolonged exposure may lead to oxidation and performance degradation, necessitating consideration of oxidation protection in high-temperature applications.

Conclusion and Outlook

Carbide materials hold an irreplaceable position in the industrial sector due to their unique hardness characteristics. With continuous advancements in preparation technologies, nanostructured carbides and composite carbide materials will become key focus areas for future development, promising to play significant roles in more fields.

In high-end manufacturing, ultra-hard carbide tools and wear-resistant components will support the development of precision machining technology, improving product processing accuracy and quality. In the new energy sector, silicon carbide power devices will drive efficiency improvements in electric vehicles and renewable energy systems, contributing to the development of green energy. In aerospace, carbide-based composite materials will meet performance requirements under extreme environments, ensuring the safe and reliable operation of aerospace equipment. In the electronics industry, novel carbide materials like MXene will expand the application boundaries of electronic devices, providing more possibilities for innovation in electronic technology.

During material selection, factors such as hardness, toughness, corrosion resistance, and cost must be comprehensively considered. Optimizing the carbide type and composite ratio for specific application scenarios is essential to achieve the best performance-economic benefit ratio and promote the sustainable development of various industries.