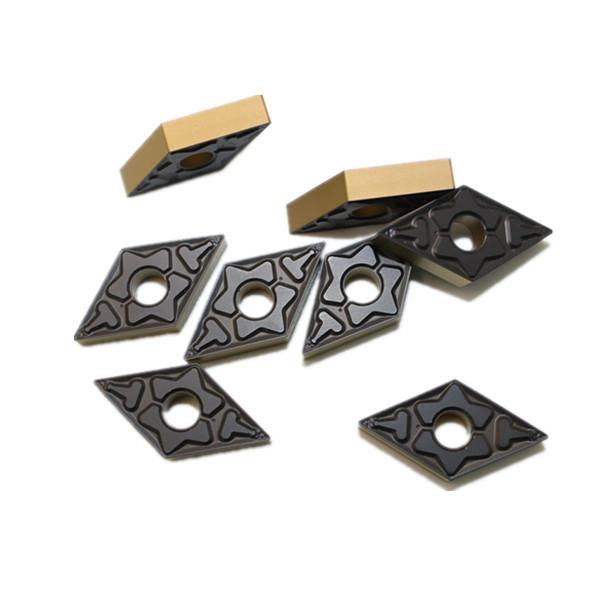

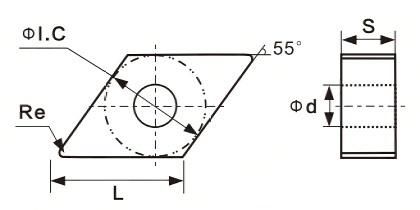

DNMG carbide inserts model; featuring the DNMG 150608

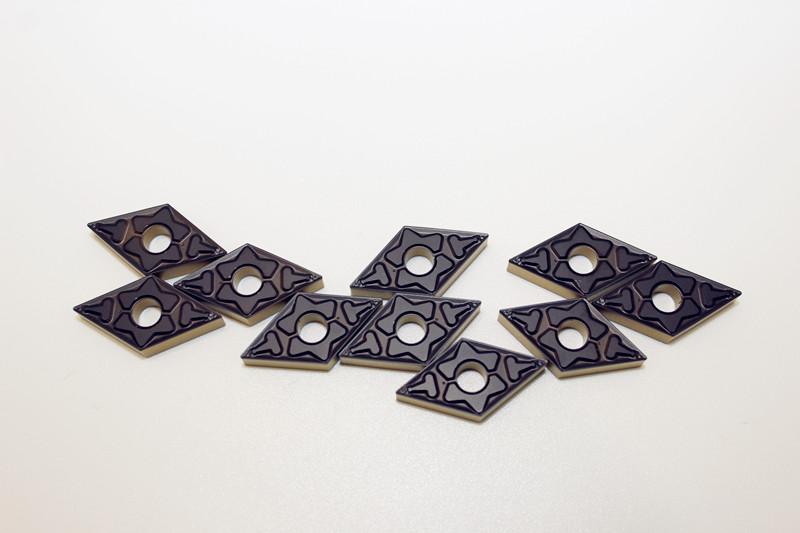

DNMG 150806 carbide insert details:

DNMG 150608 and DNMG150404 packing:

Support customized packaging.

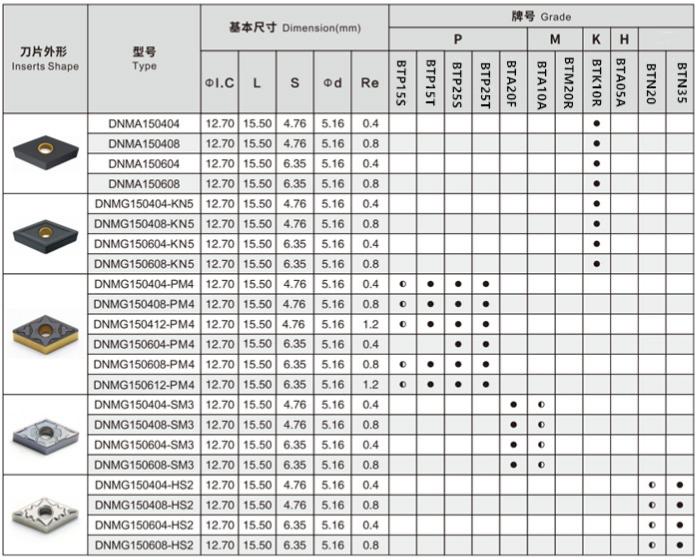

Recommended common grades for different processing metal materials:

1. For machining ordinary carbon steel and alloy steel:

Preferred choice: CVD coated inserts (such as Al₂O₃-based coatings), grades often start with M (yellow label) or P (blue label).

When high toughness is required, PVD coated TiAlN grades can be selected.

2. Processing of stainless steel and austenitic steel:

Preferred choice: PVD-coated inserts, especially those with TiAlN or AlTiN coatings. These reduce built-up edge formation and maintain a sharp cutting edge. The grade designation often starts with S (green label).

3. Machining cast iron:

Preferred choice: CVD thick coatings (such as TiCN-Al₂O₃), which offer good wear resistance and compressive strength. The grade designation usually starts with K (red label).

4. High-speed machining, high-hardness materials (hardened steel):

A heat-resistant coating (such as a CVD Al₂O₃+TiCN composite coating) must be used.

Please send us inquiries for quotations and free samples for testing: