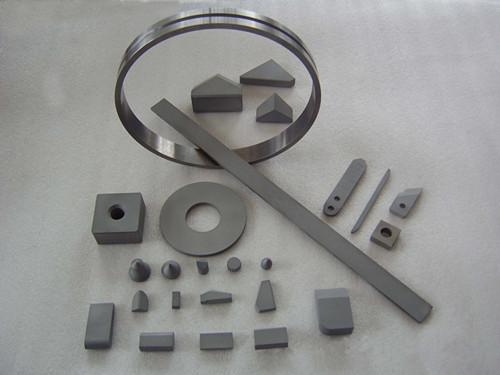

Feasibility Analysis of Tungsten Carbide Forging and Core Manufacturing Processes

I. Core Conclusion: Traditional Forging is Infeasible, but Special Processes Offer the Possibility of “Forging-like” Processes

Tungsten carbide (WC), as a typical core phase of tungsten-based cemented carbide, cannot be formed using traditional metal forging processes (such as hammer forging, roll forging, and extrusion). However, under specific temperature and pressure coupling conditions, a “forging-like” densification technology derived from powder metallurgy exists, which is fundamentally different from the plastic flow forming of traditional forging.

II. The Material Science Underlying the Infeasibility of Traditional Forging

The crystal structure and composite system characteristics of tungsten carbide fundamentally limit the feasibility of traditional forging:

1. Thermodynamic Constraints: WC has a melting point as high as 2870℃, far exceeding the temperature limit of industrial forging furnaces (conventional steel forging temperature ≤1200℃). Even at high temperatures, it has no obvious softening range, making it impossible to achieve the rheological state required for plastic deformation.

2. Contradictory Mechanical Properties: At room temperature, WC has a hardness of HRA 89-92.5 and a microhardness ≥1800HV, while its fracture toughness is only 10-15 MPa・m¹/². It is a typical “high-hardness, low-plasticity” ceramic matrix composite. Traditional forging impact loads or static pressures directly lead to intergranular bond fracture, resulting in brittle fragmentation.

3. Microstructure Limitations: Industrial WC products are typically a “WC grains + metallic binder phase” composite system (the binder phase is mostly Co or Ni, with a content of 5-15wt%). The binder phase only encapsulates the WC grains in a thin film, failing to form a continuous plastic load-bearing network and hindering overall plastic flow.

III. Core Manufacturing Processes of Tungsten Carbide (Industrial-Grade Professional Analysis)

(I) Mainstream Process: Powder Metallurgy (Accounting for over 95% of Global WC Product Production)

Powder metallurgy is the standard manufacturing route for WC products. Its core is a three-step process of “powder preparation – molding – sintering,” with the key being controlling grain size and density:

1. Powder Preparation Stage

Direct Synthesis Method: Tungsten powder (W≥99.9%, particle size 1-5μm) is mixed with carbon black/graphite powder (C≥99.5%) at an atomic ratio of W:C=1:1. A carbothermic reduction reaction occurs in a hydrogen atmosphere at 1400-1600℃: W + C → WC, generating primary WC powder (particle size 0.5-3μm). Spray drying granulation: Add 5-15wt% Co powder (binder phase) and molding agent (such as paraffin wax, polyvinyl alcohol) to WC powder, ball mill (ball-to-powder ratio 10:1, grinding time 24-72h), and then spray dry to form a flowable agglomerated powder (particle size 50-200μm).

1. Molding Stage

Cold isostatic pressing (CIP): Load the agglomerated powder into an elastic mold and press it isostatically under a pressure of 150-300MPa to obtain a green body with a relative density of 60-70%, suitable for complex-shaped products (such as knives, molds).

Compression molding: Use a steel mold to press unidirectionally under a pressure of 100-200MPa, suitable for simple shapes (such as liners, dental drill bits). It is necessary to control the uniformity of the pressing density to avoid sintering cracking.

1. Sintering Stage

Vacuum Sintering: Heating at 1350-1500℃ and a vacuum degree ≤10⁻³Pa for 1-4 hours, divided into solid-state sintering (diffusion on the WC grain surface) and liquid-phase sintering (melting of the Co-based binder phase, wetting and encapsulating the WC grains and filling pores), ultimately obtaining products with a relative density ≥99%.

Low-Pressure Sintering (LPS): Argon gas at 0.5-5MPa is introduced in the later stages of sintering to inhibit abnormal growth of WC grains and eliminate closed pores, increasing the density to over 99.5% and improving fracture toughness by 10-15%.

(II) Cutting-Edge “Forging-like” Densification Technology (Specifically for High-End WC Products)

This technology replaces the plastic deformation of traditional forging with “high temperature + dynamic pressure,” with the core objective of refining grains and increasing density:

1. Oscillating Pressure Assisted Sintering Forging (OPASF)

Process Principle: A pre-sintered blank (relative density 70-85%) is placed in a graphite mold, and periodic oscillating pressure (amplitude 5-20 MPa, frequency 10-50 Hz) is applied at 1200-1400℃. The pressure waves promote particle rearrangement and interfacial bonding.

Technical Advantages: It can achieve an ultrafine grain structure (WC grain size 250-500 nm), a relative density of 99.6%, a 5-8% increase in hardness, and a fracture toughness of 18-22 MPa・m¹/². It has been applied to aero-engine blade inserts and high-end cutting tools.

1. Hot Isostatic Pressing (HIP)

Process Parameters: Holding at 1300-1450℃ and 100-200MPa argon pressure for 2-4 hours, utilizing the high-temperature, high-pressure isostatic pressing environment to eliminate sintering defects (such as microporosity and cracks).

Applications: Used for WC-Co military products (such as armor-piercing projectile cores) and high-precision molds, increasing fatigue strength by over 30%.

2. Spark Plasma Sintering (SPS)

Process Characteristics: Rapid heating via Joule heating generated by pulsed current (heating rate 100-500℃/min), holding at 800-1200℃ and 50-150MPa pressure for 3-10 minutes, achieving rapid densification.

Core Advantages: Significantly shortens sintering time, inhibits WC grain growth (particle size ≤ 1μm), and consumes only 1/3 the energy of traditional sintering. Suitable for nanocrystalline WC products and WC-TiC-TaC multi-element alloys.

(III) Other Special Manufacturing Processes

1. Chemical Vapor Deposition (CVD): Deposits a WC coating (1-10μm thick) on the substrate surface through a gas-phase reaction (e.g., WF₆ + CH₄ + H₂ → WC + HF), used for surface strengthening of cutting tools and bearings.

2. Selective Laser Melting (SLM): Utilizes a laser beam to selectively melt and shape WC-Co powder. Suitable for complex custom-made parts (e.g., micro-molds, medical implants), but requires solving crack control and density challenges.

IV. Process Selection and Application Scenarios Matching

| Manufacturing Process | Density | Grain Size | Production Cost | Typical Applications |

| Vacuum Sintering | ≥99% | 1-5μm | Low | General-purpose cutting tools, wear-resistant liners |

| Low-Pressure Sintering | ≥99.5% | 0.8-3μm | Medium | Precision molds, engineering machinery parts |

| Hot Isostatic Pressing (HIP) | ≥99.8% | 1-4μm | High | Military products, aerospace components |

| Oscillating Pressure Sintering | ≥99.6% | 0.25-1μm | Medium-High | High-end cutting tools, wear-resistant inserts |

| Spark Plasma Sintering (SPS) | ≥99.7% | 0.5-2μm | High | Nanocrystalline products, special alloys |

V. Summary

1. Due to its high hardness, low plasticity, and high melting point, tungsten carbide is completely unsuitable for traditional forging processes. Any attempt to achieve plastic deformation through impact or static pressure will result in product breakage.

2. Industrially, powder metallurgy is the core manufacturing technology, offering advantages in both cost and mass production. For high-end applications, “forging-like” densification technologies such as oscillating pressure sintering and hot isostatic pressing can be used to achieve performance upgrades.

3. Process selection should be application-demand oriented: vacuum sintering is preferred for general-purpose wear-resistant parts; low-pressure sintering or hot isostatic pressing is used for precision load-bearing parts; and spark plasma sintering or oscillating pressure sintering can be used for ultra-high-performance components.

Our company is among China’s top ten cemented carbide manufacturers. Should you require cemented carbide products, please contact us.