Non magnetic tungsten cemented carbide grades:

| Grade | Nickel Content Ni% |

Density g/cm³ |

Hardness (HRA) |

TRS (MPa) |

Grain Size (μm) |

| YN5 | 5 | 14.75 | 92.5 | 2050 | 0.8 |

| YN6 | 6 | 14.67 | 92 | 2150 | 0.8 |

| YN8 | 8 | 14.65 | 91.5 | 2200 | 0.8 |

| YN10 | 10 | 14.45 | 90.5 | 2350 | 0.8 |

| YN14 | 14 | 14 | 88.8 | 2300 | 1 |

| YN15 | 15 | 14.15 | 88.6 | 2350 | 1.2 |

| YN20 | 20 | 13.95 | 88.5 | 2400 | 0.8 |

| YN10S | 10 | 14.5 | 92 | 2500 | 0.6 |

| YN10SX | 10 | 14.2 | 86 | 2400 | 2.5 |

| YN8S | 8 | 14.65 | 92.4 | 2200 | 0.6 |

YN5: Suitable for non-magnetic environments subjected to strong impacts and vibrations. Examples include: non-magnetic geological drilling tools, oil and mining drill bits, impact mold bases, and large non-magnetic tools.

Precision electronic molds: Due to its high hardness (HRA 92+) and low permeability, it is used to manufacture molds for forming magnetic materials, such as silicon steel sheet punching dies and permanent magnet pressing dies, avoiding interference with magnetic field distribution.

YN6: Its applications fall between YN5 and YN8, used in applications with a certain degree of impact. Examples include: general-purpose non-magnetic tools and wear-resistant parts.

YN8: The most widely used non-magnetic grade. It offers a balanced combination of hardness and toughness. Suitable for most non-magnetic molds and wear-resistant parts. Examples include: molds for forming magnetic materials (neodymium iron boron, ferrite), non-magnetic tools, and instrument parts.

YN10: Based on YN8, it appropriately improves hardness and wear resistance while maintaining a certain level of toughness. Used for general-purpose molds with higher wear resistance requirements than YN8.

YN14: High hardness and good wear resistance, but lower toughness than YN8/10. Suitable for applications where wear is the primary failure mode and impact is minimal. Examples include precision lead frame mold inserts and wear-resistant parts requiring high surface finish.

YN15: Better wear resistance than YN14, but toughness is further reduced. Suitable for precision molds requiring extremely high wear resistance and minimal impact. Examples include key inserts in semiconductor packaging molds, wire drawing dies, and precision cold heading dies.

YN20: This is a special grade, typically containing a higher nickel content, possibly emphasizing better corrosion resistance or special electrical properties while remaining non-magnetic. Used for non-magnetic wear-resistant parts in chemical environments or certain electronic components.

YN10S: Based on YN10, it optimizes certain properties (such as surface finish and cutting edge sharpness) by adjusting the carbide particle size or composition. Used for more precise molds.

YN10SX: Achieves both high hardness (wear resistance) and high strength (toughness) through the use of ultrafine WC powder. This is a high-end grade, used in extremely precise molds, such as the “blade” inserts for IC leadframes and precision stamping dies. It is both wear-resistant and not prone to chipping.

YN8S: Similar to YN10S, it is a performance-optimized version based on the general-purpose YN8, possibly to improve hardness or surface quality while retaining good toughness. It is used in general-purpose non-magnetic mold applications with higher performance requirements.

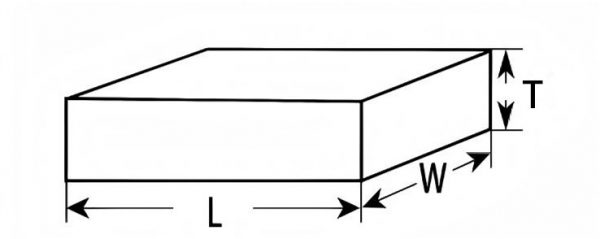

Non magnetic cemented carbide sizes:

| Dimensions(MM) | ||

| Length (0~+5) |

Width (0~+5) |

Height (+0.5~+0.6) |

| 105/200 | 105/200 | 5 |

| 105/200 | 105/200 | 10 |

| 105/200 | 105/200 | 15 |

| 105/200 | 105/200 | 20 |

| 105/200 | 105/200 | 25 |

| 105/200 | 105/200 | 30 |

| 105/200 | 105/200 | 45 |

| 105/200 | 105/200 | 50 |

| 105/200 | 105/200 | 55 |

| 105/200 | 105/200 | 60 |

| 105/200 | 105/200 | 65 |

| 105/200 | 105/200 | 70 |

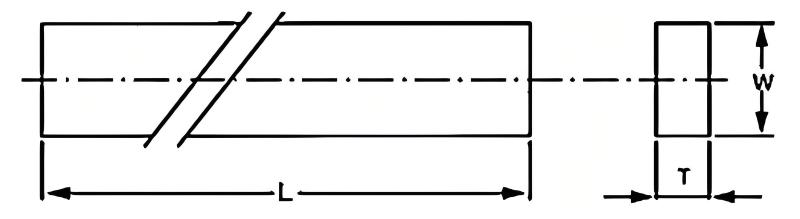

| Dimensions(MM) | ||

| Length (0~+5) |

Width (0~+5) |

Thickness (+0.5~+0.6) |

| 100~200 | 20/22/25 | 4/5 |

| 200~300 | 20/22/25/30 | 4/5 |

| 300~400 | 20/22/25/30 | 4/5 |

| 400~500 | 20/22/25/30 | 4/5 |

| 500~600 | 20/22/25 | 4/5 |

| 600~700 | 22/21/25 | 4/5 |

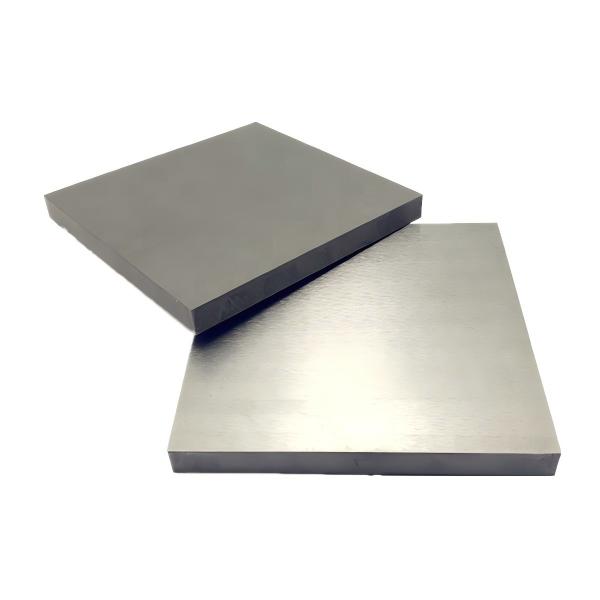

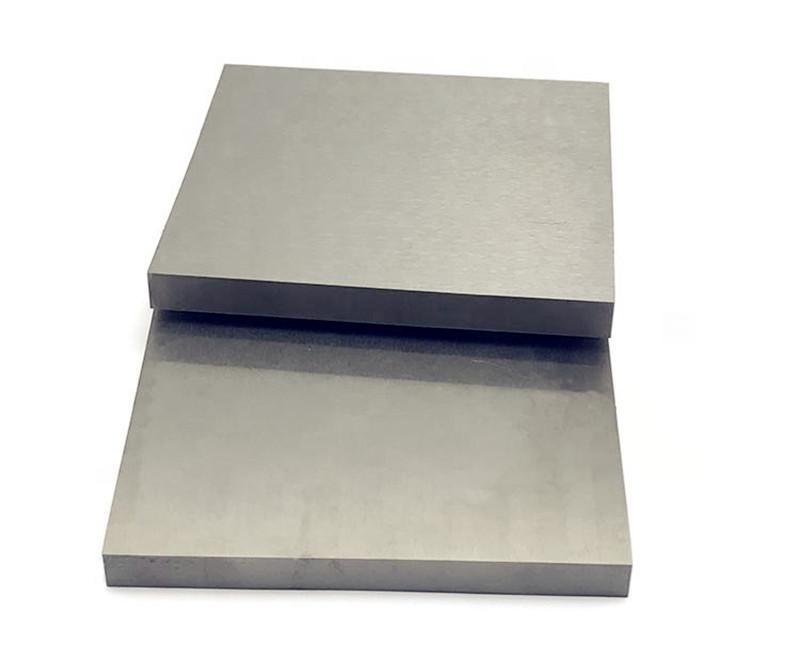

Non magnetic cemented carbide plate details:

Please send us inquiries for quotations and free samples for testing: