Tungsten carbide end mill blanks grades:

| Grade | ISO Grade | WC (%) |

Co (%) |

Grain Size (μm) |

Hardness (HRA) |

Density (g/cm³) |

TRS (N/mm²) |

| BU06 | K05 – K10 | 94 | 6 | 0.5 | 94 | 14.75 | 3600 |

| YG10X | K20 – K30 | 90 | 10 | 0.8 | 91.5 | 14.35 | 3600 |

| BT15 | K20 – K30 | 90 | 10 | 0.7 | 92.2 | 14.35 | 3900 |

| BT20 | K20 – K30 | 90 | 10 | 0.6 | 92.3 | 14.4 | 4000 |

| BT25 | K30 – K40 | 88 | 12 | 0.6 | 92.5 | 14.1 | 4000 |

| BT25UF | K30 – K40 | 88 | 12 | 0.4 | 92.8 | 14.05 | 4200 |

Grade BU06: This grade is suitable for machining aluminum magnesium alloy, graphite, plastic, wood and composite material, etc.

Grade YG10X: This grade is suitable for machining materials such as common steel, non-ferrous metals, and cast iron, etc. It can process materials with hardness up to HRC 45.

Grade BT15: This grade is suitable for machining common steel, cast iron, stainless steel, heat-resistant steel, chilled hardened steel, nickel base alloy and titanium alloy, etc. It can process materials with hardness up to HRC 55.

Grade BT20: This grade is suitable for machining stainless steel, heat-resistant steel, chilled hardened steel, cast iron, nickel base alloy and titanium alloy, etc. It can process materials with hardness up to HRC 55.

Grade BT25: This grade is suitable for machining alloy steel, titanium alloy, chilled hardened steel cast iron, aluminium alloy, etc. It can process materials with hardness up to HRC 58.

Grade BT25UF: This grade is suitable for machining alloy steel, stainless steel, aluminium alloy, chilled hardened steel and titanium alloy, etc. It can process materials with hardness up to HRC 65.

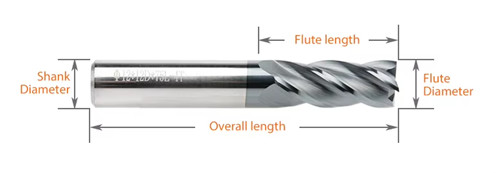

Tungsten carbide end mill sizes:

| Specification | Diameter | Cutting Length | Shank | Total length | Flutes |

| 3*8*3*50 | 3 | 8 | 3 | 50 | 2/4 |

| 3*12*3*75 | 3 | 12 | 3 | 75 | 2/4 |

| 3*15*3*100 | 3 | 15 | 3 | 100 | 2/4 |

| 1*3*4*50 | 1 | 3 | 4 | 50 | 2/4 |

| 1.5*4*4*50 | 1.5 | 4 | 4 | 50 | 2/4 |

| 2*5*4*50 | 2 | 5 | 4 | 50 | 2/4 |

| 2.5*7*4*50 | 2.5 | 7 | 4 | 50 | 2/4 |

| 3*8*4*50 | 3 | 8 | 4 | 50 | 2/4 |

| 3.5*10*4*50 | 3.5 | 10 | 4 | 50 | 2/4 |

| 4*10*4*50 | 4 | 10 | 4 | 50 | 2/4 |

| 4*16*4*75 | 4 | 16 | 4 | 75 | 2/4 |

| 4*20*4*100 | 4 | 20 | 4 | 100 | 2/4 |

| 5*13*5*50 | 5 | 13 | 5 | 50 | 2/4 |

| 5*20*5*75 | 5 | 20 | 5 | 75 | 2/4 |

| 5*25*5*100 | 5 | 25 | 5 | 100 | 2/4 |

| 1*3*6*50 | 1 | 3 | 6 | 50 | 2/4 |

| 1.5*4*6*50 | 1.5 | 4 | 6 | 50 | 2/4 |

| 2*5*6*50 | 2 | 5 | 6 | 50 | 2/4 |

| 2.5*7*6*50 | 2.5 | 7 | 6 | 50 | 2/4 |

| 3*8*6*50 | 3 | 8 | 6 | 50 | 2/4 |

| 3.5*10*6*50 | 3.5 | 10 | 6 | 50 | 2/4 |

| 4*10*6*50 | 4 | 10 | 6 | 50 | 2/4 |

| 4.5*12*6*50 | 4.5 | 12 | 6 | 50 | 2/4 |

| 5*13*6*50 | 5 | 13 | 6 | 50 | 2/4 |

| 5.5*15*6*50 | 5.5 | 15 | 6 | 50 | 2/4 |

| 6*15*6*50 | 6 | 15 | 9 | 50 | 2/4 |

| 6*25*6*75 | 6 | 25 | 6 | 75 | 2/4 |

| 6*30*6*100 | 6 | 30 | 6 | 100 | 2/4 |

| 6*40*6*150 | 6 | 40 | 6 | 150 | 2/4 |

| 7*18*8*60 | 7 | 18 | 8 | 60 | 2/4 |

| 8*20*8*60 | 8 | 20 | 8 | 60 | 2/4 |

| 8*28*8*75 | 8 | 28 | 8 | 75 | 2/4 |

| 8*35*8*100 | 8 | 35 | 8 | 100 | 2/4 |

| 8*50*8*150 | 8 | 50 | 8 | 150 | 2/4 |

| 9*23*10*75 | 9 | 23 | 10 | 75 | 2/4 |

| 10*25*10*75 | 10 | 25 | 10 | 75 | 2/4 |

| 10*40*10*100 | 10 | 40 | 10 | 100 | 2/4 |

| 10*50*10*150 | 10 | 50 | 10 | 150 | 2/4 |

| 11*28*12*75 | 11 | 28 | 12 | 75 | 2/4 |

| 12*30*12*75 | 12 | 30 | 12 | 75 | 2/4 |

| 12*45*12*100 | 12 | 45 | 12 | 100 | 2/4 |

| 12*60*12*150 | 12 | 60 | 12 | 150 | 2/4 |

| 14*35*14*80 | 14 | 35 | 14 | 80 | 2/4 |

| 13*45*14*100 | 13 | 45 | 14 | 100 | 2/4 |

| 14*45*14*100 | 14 | 45 | 14 | 100 | 2/4 |

| 14*60*14*150 | 14 | 60 | 14 | 150 | 2/4 |

| 15*45*16*100 | 15 | 45 | 16 | 100 | 2/4 |

| 16*45*16*100 | 16 | 45 | 16 | 100 | 2/4 |

| 16*60*16*150 | 16 | 60 | 16 | 150 | 2/4 |

| 18*45*18*100 | 18 | 45 | 18 | 100 | 2/4 |

| 18*70*18*150 | 18 | 70 | 18 | 150 | 2/4 |

| 20*45*20*100 | 20 | 45 | 20 | 100 | 2/4 |

| 20*70*20*150 | 20 | 70 | 20 | 150 | 2/4 |

Our company supports customization of carbide end mill size and shape, welcome to send us drawings.

Carbide end mill details:

Coating:

| Details | TiN | TiAIN | AITiN | TISIN | Nano Blue | DLC |

| Color | Golden | Purple | Black | antique brass |

Dazzle blue | Dazzle black |

| HV | 2300 | 3200 | 3400 | 3600 | 42(GPA) | 1000~4000 |

| Thickness/ μm |

0.4 | 0.5 | 0.5 | 0.4 | 0.4 | 0.5-2.0 |

| Friction coefficient |

0.4 | 0.35 | 0.4 | 0.45 | 0.4 | 0.05 |

| MAX Temperature |

500 | 800 | 900 | 1000 | 1200 | 400 |

| Description |

Cost-effective. |

General. |

High speed milling and high HRC material. |

Processing copper, titanium and mold Steel. |

General high speed milling. |

Non-ferrous metals, graphite and plastics. |

Please send us inquiries for quotations and free samples for testing: