Tungsten carbide preforms grade:

| Grade | ISO Grade | WC (%) |

Co (%) |

Grain Size (μm) |

Hardness (HRA) |

Density (g/cm³) |

TRS (N/mm²) |

| BU06 | K05-K10 | 94 | 6 | 0.5 | 94 | 14.75 | 3600 |

| YG10X | K20 – K30 | 90 | 10 | 0.8 | 91.5 | 14.35 | 3600 |

| BT15 | K20 – K30 | 90 | 10 | 0.7 | 92.2 | 14.35 | 3900 |

| BT20 | K20 – K30 | 90 | 10 | 0.6 | 92.3 | 14.4 | 4000 |

| BT25 | K30 – K40 | 88 | 12 | 0.6 | 92.5 | 14.1 | 4000 |

| BT25UF | K30 – K40 | 88 | 12 | 0.4 | 92.8 | 14.05 | 4200 |

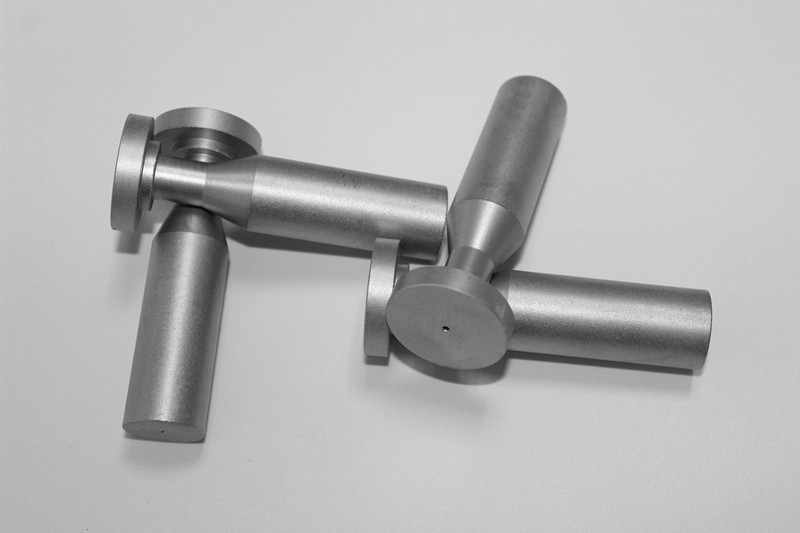

Carbide preforms details:

Our experience:

With decades of expertise in non-standard hard alloy manufacturing, Bortome Carbide has established a state-of-the-art production line in China, specializing in precision-engineered carbide prefabricated parts.

Leveraging advanced CIP (Cold Isostatic Pressing) billet forming technology and a fully integrated production system, we offer flexible order policies with no minimum quantity requirements, coupled with customized solutions tailored to client-specific blueprints. Our capabilities are further enhanced by a partner network providing precision grinding services and global express delivery, ensuring rapid fulfillment of complex, geometrically challenging tool blank materials.

Please send us inquiries for quotations and free samples for testing: