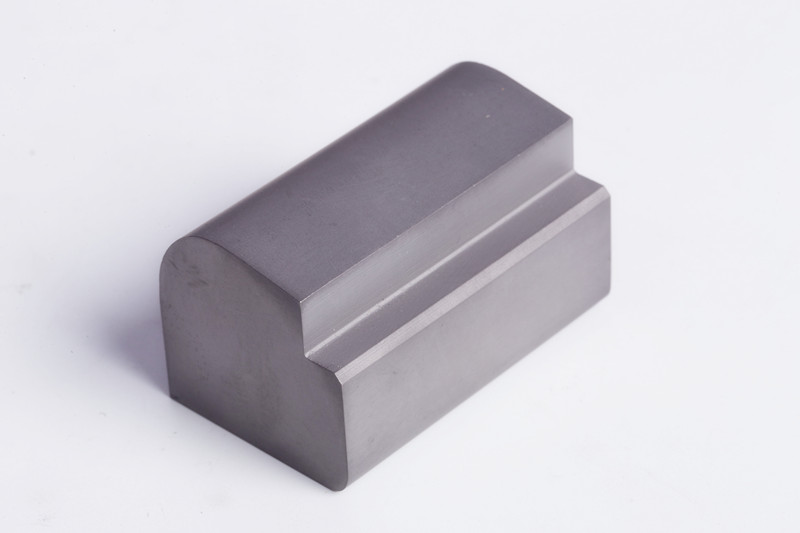

Tungsten carbide wear parts for mining crushing grades:

| Grade | Co(%) | Density (g/cm³) |

Hardness (HRA) |

Average Grain Size (μm) |

TRS (N/mm²) |

| BK5 | 6 | 14.90 | 88.0 | 3-5 | 2300 |

| BK3 | 8 | 14.70 | 87.0 | 3-5 | 2400 |

| BK2 | 9 | 14.60 | 86.7 | 3-5 | 2450 |

| BK1 | 10 | 14.50 | 86.3 | 3-5 | 2500 |

| BK13 | 13 | 14.20 | 85.5 | 3-5 | 2700 |

| BK15 | 15 | 14.00 | 84.5 | 3-5 | 2900 |

| BCK13 | 13 | 14.20 | 85.0 | 4-7 | 2650 |

| YG11C | 11 | 14.40 | 86.5 | 2-3 | 2450 |

| YG13C | 12 | 14.30 | 86.0 | 2-3 | 2500 |

| YG15C | 14 | 14.10 | 85.5 | 2-3 | 2600 |

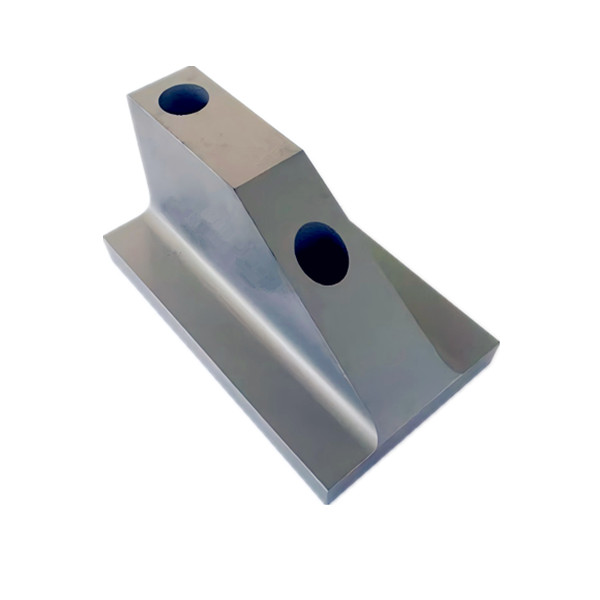

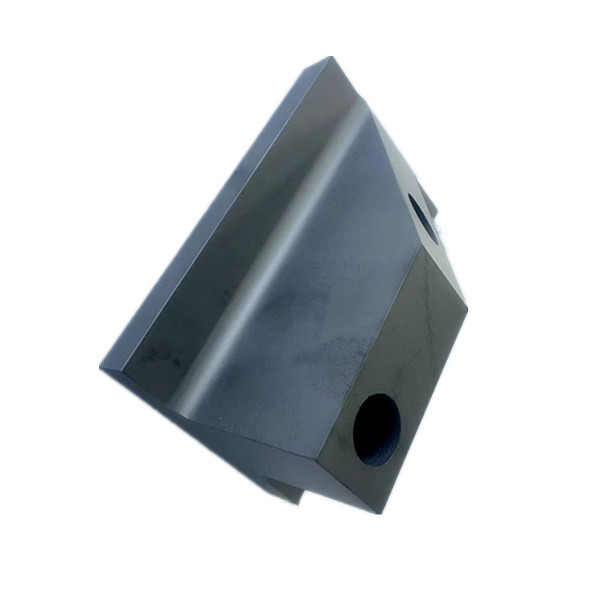

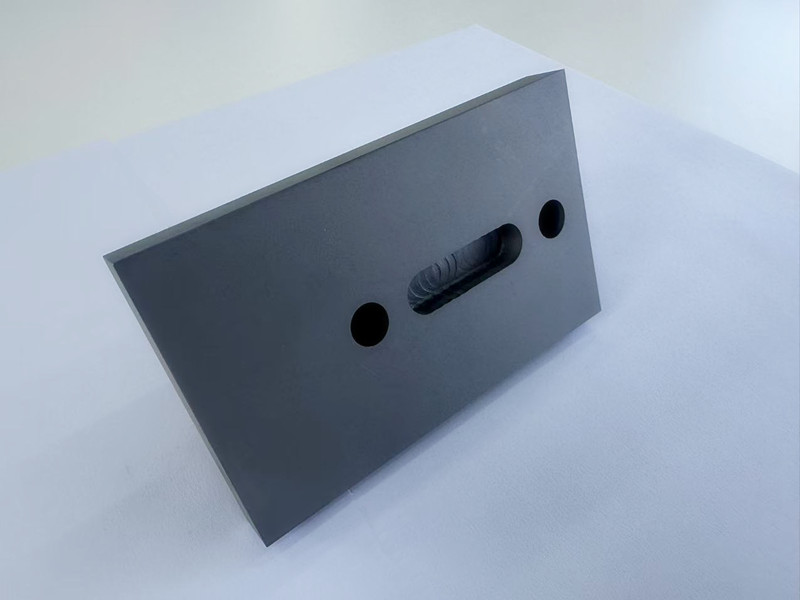

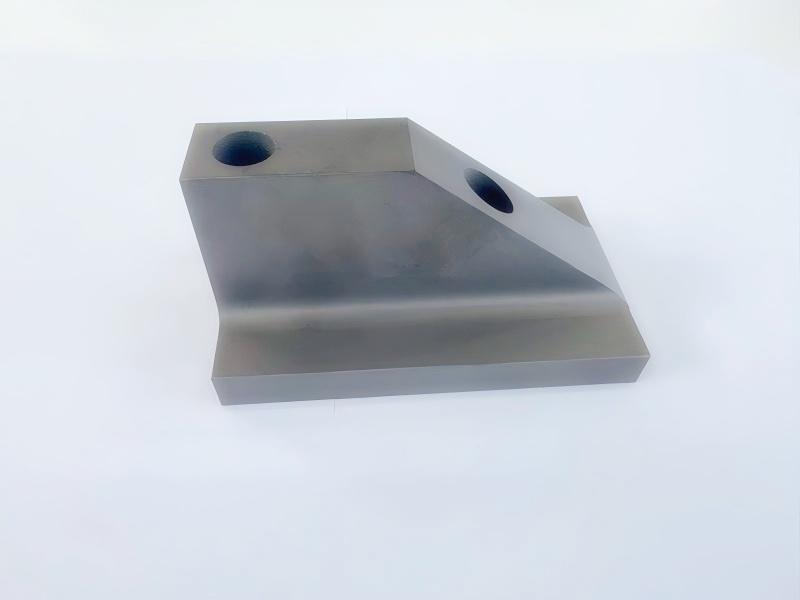

Tungsten carbide wear parts for mining crushing details:

Our customer background for carbide inserts: We supply tungsten carbide inserts for China Railway Group (CREC),Vermeer, etc.

Please send us inquiries for quotations and free samples for testing: