Silicon carbide vs tungsten carbide

How to better understand silicon carbide vs tungsten carbide. This article provides a comparative analysis of silicon carbide (SiC) vs tungsten carbide (WC), focusing on their properties and industrial applications.

1. Silicon Carbide (SiC)

Density: 3.2 g/cm³.

Primary Variants:

Black SiC (α-SiC, 98.5% purity): Exhibits higher toughness than green SiC, primarily used for machining low-tensile materials (glass, ceramics, cast iron).

Green SiC (α-SiC, >99% purity): Superior self-sharpening properties, ideal for cemented carbides, titanium alloys, and precision grinding of high-speed steel tools.

Cubic SiC: A yellow-green crystal synthesized via specialized methods, used for ultra-precision bearing machining, reducing surface roughness from Ra 32–0.16 μm to Ra 0.04–0.02 μm.

Key Properties:

High thermal conductivity (120–490 W/m·K)

Semiconductor behavior with oxidation resistance up to 1600°C

Chemically inert in acidic/alkaline environments (pH 3–11)

Applications:

Turbine blade coatings (extends service life by 100–200%)

Energy-efficient refractories (low thermal expansion, high thermal shock resistance)

Deoxidizers in steelmaking (85% purity grade)

Heating elements (e.g., silicon carbide rods)

2. Silicon Nitride (Si₃N₄)

Structure: Diamond-like 3D lattice.

Properties:

Melting point: 1900°C

Density: 3.2–3.4 g/cm³ | Hardness: 1500–1900 HV

Flexural strength: 600–1000 MPa | Elastic modulus: 310 GPa

Stable in air up to 1450–1550°C

Soluble in HF; inert to water and dilute acids

3. Tungsten Carbide (WC)

Structure: Hexagonal crystal (metallic luster).

Properties:

Density: 15.63 g/cm³ (18°C) | Melting point: 2870°C

Insoluble in H₂O, HCl, H₂SO₄; soluble in HNO₃-HF mixtures

Brittleness reduced by adding Ti/Co (1–5 wt%)

Synthesis:

Produced via carburization of tungsten powder at 1400–1600°C.

Oxide-derived WC requires vacuum treatment at 1500°C.

Applications:

Cutting tools (with TiC/TaC additives for impact resistance)

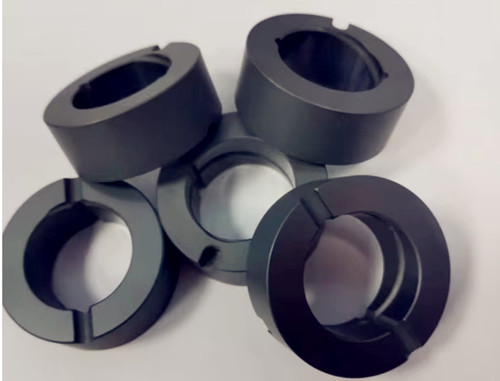

High-temperature components (carbide nozzles, jet engines, carbide seals)

Structural Insight:

Carbon atoms occupy interstitial sites in the tungsten lattice, forming an interstitial solid solution.

4. Mechanical Seal Lifespan in Sewage Pumps

[Q]: How long do sewage pump mechanical seals last?

[A]: Depends on material and operating conditions:

Tungsten carbide: 1–2 years

Silicon carbide: ~1 year

Ceramic: <6 months